Table of Contents

Introduction

Modern technology and changing consumer requirements are causing a significant shift in the warehouse and inventory management industry. Artificial intelligence (AI), robots, the Internet of Things (IoT), and data analytics are just a few of the technological innovations that have completely transformed traditional warehouse operations and improved supply chain flexibility. These innovative business trends include a wide range of revolutionary inventions. Automation utilizes robots and self-governing systems to reduce error and increase production.

Predictive analytics for accurate inventory control, demand forecasting, and optimal storage utilization are employed by AI and machine learning. The incorporation of cloud-based technologies enhances the capability for real-time management and monitoring in several locations. The important trends influencing inventory management and warehousing are highlighted in this article, with a focus on how they affect operations and the ongoing changes in the industrial landscape.

Importance

- Real-time warehouse data offers instant supply adjustments and cost savings. This allows for rapid response to demand changes, increasing inventory levels and significantly reducing operational costs.

- The use of conversational AI in analytics frees planners from tedious data mining tasks, allowing for faster and easier decision-making. The AI’s ability to accurately understand complex data streamlines analytics, enhancing accuracy and speed in inventory management processes.

- Custom Digital Twin solutions provide planners with a virtual test bed to simulate and anticipate future demand fluctuations. This cutting-edge tool allows scenario planning to better anticipate market changes and improve overall inventory management flexibility to effectively respond to changing market demands.

Challenges

- Legacy System Adaptation – Lots of companies have a hard time integrating or using supply chain planning solutions. A lot of it has to do with the time and effort it takes to change or update old systems to keep up with new tech. As a result, inventory management is often slow and needs a lot of manual changes to keep up with the ever-changing needs of the market.

- Data Overload and Analysis – Handling complex supply chain tower systems may be a common problem that requires a lot of data analysis effort. The process of deriving significant insights from large datasets may impede prompt decision-making and operational flexibility.

- Implementation and Learning Curve – Processes that involve long-term planning and scenario planning often take a lot of time and resources. Packing solutions or adopting new technologies can put planners on a learning curve, which can prevent them from making timely and efficient decisions because of the complexity involved.

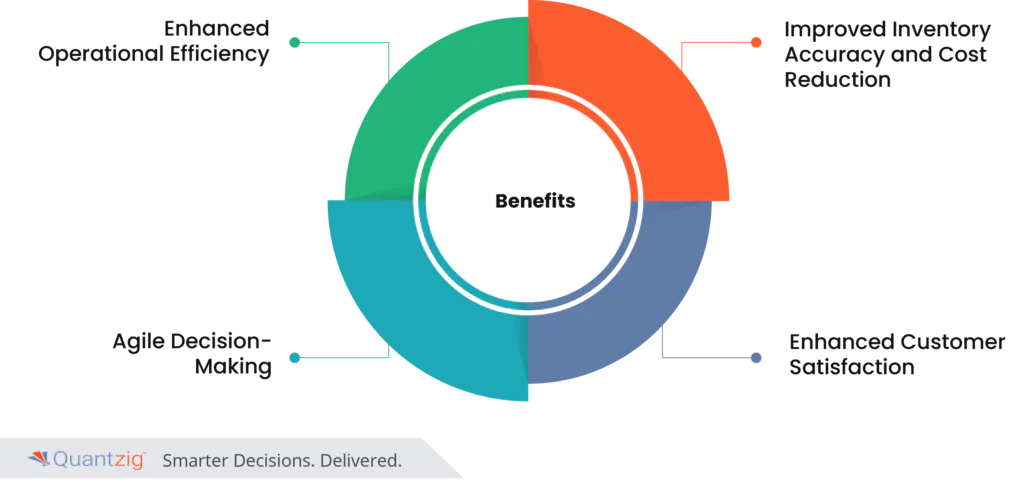

Benefits

- Enhanced Operational Efficiency – The utilization of cutting-edge technologies, such as Artificial Intelligence-based solutions and instantaneous access to data, facilitates warehouse operations, resulting in a decrease in manual labor and an increase in overall efficiency. This efficiency leads to smoother operations and faster responses to changing requirements.

- Improved Inventory Accuracy and Cost Reduction – Advanced technologies facilitate accurate demand prediction and inventory management. The implementation of predictive analytics and the utilization of machine learning significantly reduces the occurrence of overstock or stockout, thereby optimising inventory levels and reducing the associated holding costs.

- Agile Decision-Making – With real-time data, it’s possible to make faster, more agile decisions. Planners are able to react quickly to market changes, adjusting inventory and supply chain levels in real time. This flexibility allows for faster, more impactful decisions.

- Enhanced Customer Satisfaction - The implementation of effective inventory management can lead to enhanced customer service. Forecasting accurately can help to meet customer demand, reduce lead times, and avoid stockouts, thus increasing customer satisfaction and fostering loyalty.

Conclusion

Warehouse and inventory management have changed a lot in the last few years, and it’s all thanks to cutting-edge tech. AI-powered solutions, easy access to data, and analytics have revolutionized operations. They’ve made inventory control more accurate, made operations more efficient, and made supply chain decisions more responsive. Forecasting demands, adjusting inventory quickly, and adapting to market changes all help make operations more efficient and cost-effective. Adopting these advanced strategies not only helps you stay competitive, but also sets the stage for meeting customer needs while improving warehouse management and customer satisfaction.

Success Story

Client Details –

A Leading Company located in Europe.

Challenges faced by the Client

- The client faced a number of difficulties while utilizing a Supply Chain Planning tool, and was cognizant of the labor-intensive nature of the process of updating inventory parameters to match demand projections. This inefficiency led to a lack of effective inventory management as the system necessitated a large number of manual adjustments to align stock levels to market demands, leading to delays and potential supply chain inaccuracies.

- One of the major challenges that planners faced while navigating complex supply chain tower systems was the time-consuming process of extracting meaningful information from a large amount of data. The hours spent analyzing this large amount of data resulted in delays in the decision-making process, impeding the ability to react quickly to changes in the market or unforeseen requirements within the warehouse or inventory management system.

- Long term and scenario planning required a lot of time and effort from planners. Packed solutions presented a huge learning curve. Due to the complexity of packaged solutions, the planners were unable to make timely and efficient decisions. This hampered the adaptation and efficient use of new technologies, which had a negative impact on the effectiveness and responsiveness of inventory management system.

Solutions Offered by Quantzig

- Quantzig offered an integrated suite of AI-powered planning and inventory solutions to streamline forecasting and quickly adjust inventory levels. With this adaptive approach, planners could immediately respond to real-time changes in demand, expected cancellations and product shrinkage. This allowed for actionable, day-ahead planning in real-time, allowing for better decision-making and improved overall operational efficiency across the supply chain.

- With their Interactive Q&A based reporting system, they were able to significantly reduce the amount of time spent on analysis and provide insightful recommendations like interacting with an Oracle. They were able to identify and highlight issues effectively, allowing them to solve problems quickly and efficiently for the whole team, allowing them to quickly resolve issues during inventory management.

- Quantzig gave teams access to simulation-based scenario planning through the use of specialised scenario tools. These tools enabled teams to create future situations with simple drag-and-drop functionality. This creative method streamlined the planning process and added to increased operational effectiveness in the warehouse and inventory management domains by not only identifying possible failure areas but also offering advise on essential modifications in inventory configurations.

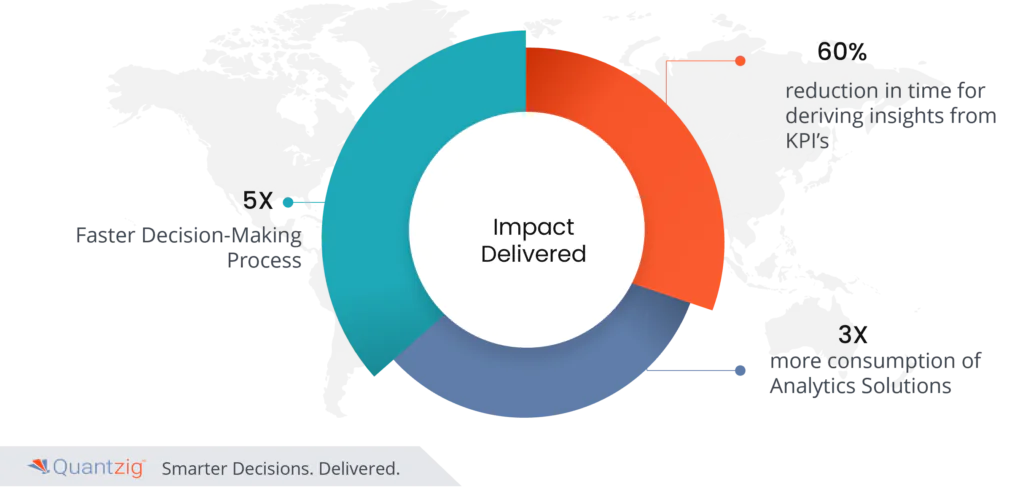

Impact Delivered

- 5X Faster Decision-Making Process – The implementation of cutting-edge technologies within the warehouse and inventory management process resulted in a significant acceleration in decision-making, with a 5x increase in the ability to respond to supply chain changes.

- 60% reduction in time for deriving insights from KPI’s – Additionally, the adoption of modern tools resulted in a 60% decrease in the time needed to obtain insights from KPIs. The use of innovative analytics tools enabled faster access to essential information, allowing for more rapid decision making and agility in reacting to market changes.

- 3X more consumption of Analytics Solutions – The use of analytics solutions increased threefold, demonstrating the success of the integration of data driven tools. This improved consumption enabled decision-making effectiveness and flexibility within the warehousing and stock management processes, resulting in a more efficient and responsive supply chain system.

Implementations/Techstack Used

- Microsoft Power Platform

- Azure Data Factory