Written By: Sudeshna Ghosh

Table of Contents

Introduction

In the ever-evolving landscape of manufacturing, staying competitive is not just a goal, but a necessity. To thrive in this dynamic environment, manufacturers must constantly seek ways to optimize their operations, reduce costs, and enhance profitability. Enter spend analytics, a formidable game changer that has emerged as a critical tool in the arsenal of manufacturers worldwide. This article delves into the transformative power of spend analytics for manufacturers, shedding light on how it empowers businesses to make data-driven decisions, streamline procurement processes, and unlock unprecedented efficiencies. Prepare to embark on a journey that explores the revolutionary impact of spend analytics on the manufacturing industry.

Book a demo to experience the meaningful insights we derive from data through our analytical tools and platform capabilities. Schedule a demo today!

Request a Free DemoKey Benefits of Spend Analytics for Manufacturers:

1. Reduction in procurement costs

Spend analytics offer manufacturers a potent means to curtail procurement costs, a fundamental objective in the realm of manufacturing efficiency. By harnessing the power of data analytics, manufacturers gain granular insights into their spending patterns, supplier performance, and purchasing behaviors. This deep understanding allows for strategic decision-making, including supplier negotiation, consolidation of purchasing, and demand forecasting. Through the identification of cost-saving opportunities, such as bulk purchasing or supplier diversification, manufacturers can optimize their procurement processes. Consequently, they can negotiate better terms, eliminate unnecessary expenditures, and ultimately realize substantial reductions in procurement costs, contributing directly to improved profitability and sustained competitiveness in the market.

2. Better immunity against price hikes and inflation

Spend analytics provide manufacturers with a crucial advantage in mitigating the impact of price hikes and inflation. By scrutinizing historical spending data and tracking market trends, manufacturers can proactively identify cost fluctuations and potential price increases among their suppliers. Armed with this knowledge, they can negotiate long-term contracts with price protection clauses or seek alternative suppliers to secure stable pricing. Furthermore, spend analytics enable efficient inventory management, ensuring that manufacturers maintain optimal stock levels to buffer against sudden price surges. This proactive approach not only shields manufacturers from unforeseen cost escalations but also enhances financial stability and resilience in the face of economic volatility.

3. Supply and sourcing risk mitigation

Spend analytics serve as a vital tool for manufacturers in effectively mitigating supply and sourcing risks. By leveraging historical spending data and supplier performance metrics, manufacturers can assess the reliability and resilience of their supply chain partners. This proactive approach enables the identification of potential vulnerabilities and allows for the development of contingency plans to address disruptions such as natural disasters, geopolitical instability, or supplier insolvency. Additionally, spend analytics enable diversification of the supplier base, reducing dependency on a single source and spreading risk. Ultimately, this risk mitigation strategy safeguards the continuity of manufacturing operations, ensuring uninterrupted production, strategic sourcing process, and delivery even in the face of unforeseen challenges.

Experience the advantages firsthand by testing a customized complimentary pilot designed to address your specific requirements. Pilot studies are non-committal in nature.

Request a Free PilotThe Importance of Spend Analysis:

The importance of spend analysis cannot be overstated in today’s competitive business environment. It serves as a guiding compass for procurement organizations, enabling them to navigate risks and capitalize on opportunities. Through the integration of AI and BI technologies, businesses unlock actionable intelligence, identify material and component spend categories, driving continuous improvement in procurement processes and fostering sustainable growth.

In summary, spend analysis transcends mere data analysis; it embodies a strategic imperative driving organizational excellence and resilience. By embracing its methodologies and harnessing its insights, businesses chart a course towards procurement success, maximizing savings opportunities, and fortifying their strategic positioning in the marketplace.

Why Spend Analysis is Important in Procurement?

In the landscape of strategic sourcing and procurement, spend analysis emerges as a cornerstone process essential for organizational success. At its core, spend analysis involves a meticulous examination of procurement spend data across various material and component spend categories, manufacturing process groups, and supplier analysis dimensions. This comprehensive scrutiny provides unparalleled visibility into expenditure patterns, enabling businesses to capitalize on cost-saving opportunities and fortify their competitive edge.

Deciphering Spend Analysis Methodology:

Manufacturing spend analysis methodology lies at the heart of effective procurement strategies. By leveraging advanced procurement analytics tools, procurement and sourcing managers dissect procurement spend data to extract actionable insights on outliers, and drive informed decision-making. This methodical approach extends to scrutinizing procurement spend data management processes and strategic sourcing process, ensuring accuracy, and completeness for robust analysis.

Enhancing Visibility and Strategic Insights:

Visibility into procurement spend is pivotal for organizations seeking to optimize their expenditure landscape and drive strategic initiatives. Through meticulous spend analysis, businesses gain strategic insights into their procurement organizations and supply-chain performance, identifying savings opportunities, and mitigating risks. This heightened visibility empowers stakeholders to negotiate favorable terms, classify manufacturing process groups, and leverage the organization’s buying power for mutual benefit.

Capitalizing on Cost-Saving Opportunities:

Cost-saving opportunities abound within the procurement landscape, waiting to be unearthed through rigorous spend analysis. By harnessing actionable spend intelligence derived from comprehensive analysis, businesses identify inefficiencies, streamline processes, and drive down operational costs. These savings opportunities not only bolster the organization’s bottom line but also enhance its agility and resilience in a dynamic marketplace.

Enhancing Strategic Decision-Making:

Visibility into procurement spend categories and manufacturing process groups is crucial for informed strategic decision-making within procurement organizations. By leveraging manufacturing spend analysis methodology, businesses can gain deep insights into their procurement spend, identifying cost-saving opportunities and optimizing their strategic sourcing process. This enhanced visibility empowers procurement teams with strategic insights, enabling them to negotiate better terms with suppliers, maximize savings opportunities, and bolster the organization’s competitive edge.

Mitigating Risks and Maximizing Savings:

Procurement spend analysis serves as a proactive measure against risks inherent in the supply chain management. By scrutinizing procurement spend data and identifying potential risks, organizations can implement mitigation strategies to safeguard operations. Moreover, through meticulous spend analysis, businesses can uncover hidden savings opportunities, capitalize on economies of scale, and optimize procurement spend, thus enhancing the organization’s buying power and bottom line.

Driving Operational Efficiency and Performance:

A comprehensive spend analysis benefits not only procurement but also the overall organization by driving operational efficiency and enhancing supply chain performance. By optimizing material and component spend categories, businesses streamline manufacturing processes, minimize waste, and improve resource utilization. This results in cost savings, improved supply chain visibility, and ultimately, better strategic insights for procurement organizations to navigate future challenges effectively.

How to Unlock Procurement Excellence Through Spend Analysis?

In today’s dynamic business landscape, spend analysis emerges as a cornerstone process in procurement, offering organizations invaluable insights into their purchasing activities and supplier relationships. By harnessing advanced tools and techniques, procurement professionals delve deep into their spend data, analyzing purchases, suppliers, and costs to drive strategic decisions and cost-saving initiatives. Through meticulous scrutiny of procurement data, organizations can identify cost outliers, pinpoint opportunities for renegotiation, and unearth redesign opportunities to optimize product costs. Moreover, spend analysis enables procurement teams to validate savings, enhance supplier relationships, and mitigate risks associated with supplier performance and market changes. Leveraging tools like Microsoft Power BI, Tableau, or QlikView, organizations can transform raw procurement data into actionable insights, driving process efficiency, contract compliance, and ultimately, achieving substantial cost savings. With a data-driven approach to sourcing, organizations can benchmark performance, identify consolidation opportunities, and capitalize on sourcing potential, ensuring maximum value extraction from every procurement dollar spent.

Challenges/Problems faced while implementing spend analysis:

1. High costs due to ad-hoc procurement

One of the significant challenges encountered during the implementation of spend analysis is the high costs associated with ad-hoc procurement practices. Ad-hoc procurement often leads to decentralized purchasing across various departments or individuals within an organization, resulting in fragmented data sources and inconsistent processes. When transitioning to a centralized spend analysis system, organizations must invest in data consolidation, integration, and cleansing efforts, which can be resource-intensive. The costs of implementing robust spend analytics software and training personnel to utilize it effectively can also be substantial. These initial expenses can pose a barrier to entry for some organizations, making the transition to spending analysis a challenging undertaking. However, the long-term benefits often justify these initial investments in procurement efficiency and cost reduction goals.

2. Longer tail spending and poor spending categorization

Implementing spend analysis often faces challenges related to longer tail spending and poor spending categorization. Longer tail spending refers to a large number of small, infrequent purchases that can be scattered across various categories, making them difficult to track and analyze. Additionally, poor spending categorization arises from inconsistent or inaccurate data classification, leading to an incomplete or inaccurate picture of spending patterns. These challenges hinder the ability to extract meaningful insights from the data, making it challenging to identify cost-saving opportunities and supplier consolidation strategies. Overcoming these issues requires meticulous data cleansing, standardized categorization processes, and sophisticated spend analysis tools to handle the complexity of longer-tail spending.

3. Poor spend traceability leads to financial compliance failure

A significant challenge in implementing spend analysis is the risk of poor spend traceability, which can result in financial compliance failures. Inaccurate or incomplete tracking of expenditures and product manufacturing spend can lead to non-compliance with financial regulations and reporting requirements. This can result in penalties, legal issues, and damage to an organization’s reputation. Poor spend traceability may also obscure potential instances of fraud or unethical spending practices. To address this challenge, organizations must establish robust data capture and categorization processes, implement clear spending policies, and deploy advanced spend analytics tools to ensure transparency and accuracy in financial reporting. Failure to do so can have severe financial and reputational consequences.

Quantzig’s Success Story

Client Details:

A leading manufacturing company headquartered in Europe.

The challenges faced by the Client:

The client in question was grappling with a trifecta of critical challenges in their procurement and financial management processes:

1. High Costs Due to Ad-Hoc Procurement:

The client’s procurement practices were characterized by a lack of centralized controls and compliance, and standardized processes. Ad-hoc procurement, where purchases were made sporadically by various departments or individuals, resulted in inefficiencies and increased costs. This decentralized approach meant that they were not leveraging their purchasing power effectively, missing out on bulk discounts, and failing to negotiate favorable terms with suppliers. As a result, they were facing higher procurement costs, which directly impacted their bottom line.

2. Longer Tail Spends and Poor Spend Categorization:

The client struggled with a large volume of smaller, infrequent purchases scattered across different categories. This longer tail spending made it challenging to track and analyze expenditures effectively. Moreover, poor spend categorization and product manufacturing spend led to inconsistencies and inaccuracies in their financial data. This lack of visibility into their spending patterns hindered their ability to identify cost-saving opportunities and manufacturing spend analysis methodology, optimize supplier relationships, and make data-driven decisions.

3. Poor Spend Traceability Leading to Financial Compliance Failure:

Inaccurate and incomplete tracking of expenditures was exposing the client to serious financial compliance risks. Regulatory and reporting requirements were not being met due to inadequate spend traceability. This not only raised the specter of legal consequences and financial penalties but also tarnished the organization’s reputation. Instances of potential fraud or unethical spending practices could easily go unnoticed, posing further financial and reputational risks.

These challenges collectively underscored the pressing need for the client to implement a robust spend analytics solution using analytics tools such as Artificial Intelligence (AI) and Business Intelligence (BI). Such a solution would centralize procurement processes, improve spend categorization, and ensure accurate spend traceability, ultimately driving cost reduction goals, cost-reduction plans, risk mitigation, and enhanced financial compliance.

Solutions offered by Quantzig:

Quantzig provided the client with a comprehensive set of solutions that not only addressed their challenges but also empowered them to transform their procurement and financial management processes:

1. Automated Spend Categorization Using Machine Learning:

To tackle the issue of poor spend categorization and product manufacturing spend, we implemented an advanced machine learning-based solution. This automated the categorization of expenditures, eliminating inconsistencies and inaccuracies. By analyzing historical data and learning from patterns, the system ensured that every expense was accurately classified. This not only improved spending visibility but also enabled the client to make data-driven decisions with confidence. It streamlined their financial reporting processes and reduced the risk of compliance failure.

2. Supplier Selection Recommendation:

Our team leveraged data analytics to provide the client with supplier selection recommendations. By analyzing supplier performance data, market trends, and historical procurement patterns, the system identified the most suitable suppliers for each category of products or services. This optimization of supplier selection allowed the client to not only minimize costs but also mitigate supply chain risks. It ensured that they were partnering with reliable suppliers who could meet their needs consistently.

3. Tail Spend Optimization Solutions:

To address the challenge of longer tail spending, we offered tail spend optimization solutions. By identifying and aggregating smaller, infrequent purchases, the client was able to leverage its purchasing power effectively. This led to bulk discounts and improved negotiation capabilities. As a result, the client achieved significant cost reductions in the longer tail of their spending, which had previously been a source of inefficiency.

In sum, Quantzig’s tailored solutions empowered the client to overcome their challenges and transform their procurement and financial management practices. Through automated spend categorization, optimized supplier selection, and tail spend optimization, the client not only reduced costs but also enhanced compliance, minimized supply chain risks and positioned themselves for sustainable financial success in a competitive market.

Get started with your complimentary trial today and delve into our platform without any obligations. Explore our wide range of customized, consumption driven analytical solutions services built across the analytical maturity levels.

Start your Free TrialImpact Delivered:

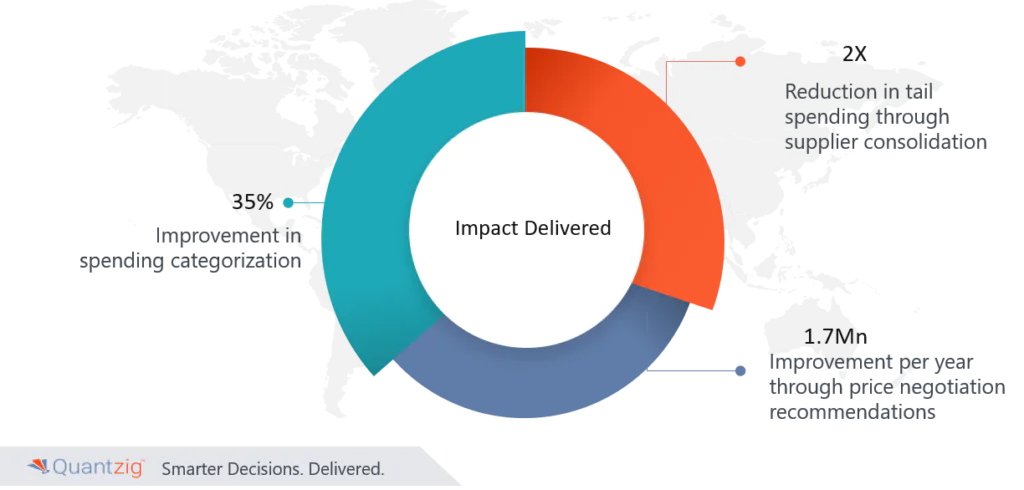

The results of implementing these solutions were remarkable:

- 35% improvement in spending categorization

- 2X reduction in tail spending through supplier consolidation

- 1.7Mn improvement per year through price negotiation recommendations

Conclusion:

In the dynamic landscape of modern manufacturing, where efficiency and profitability are paramount, spend analytics stands as an unequivocal game changer. Its transformative capabilities, from cost reduction goals to risk mitigation and supply chain optimization, empower manufacturers to excel in an ever-evolving industry. By harnessing the power of data-driven decision-making, manufacturers can navigate challenges with precision and seize opportunities with confidence. In conclusion, the adoption of spend analytics is not merely an option; it is imperative for manufacturers aiming not only to survive but to thrive in an era defined by relentless competition and unyielding market demands. Embrace it, and the future of manufacturing is yours to shape.