Table of Contents

Summary

Client: A leading global consumer packaged goods (CPG) manufacturer with an extensive product portfolio, multiple manufacturing sites, and a wide distribution network.

Challenges: The client faced a persistent challenge of frequent stockouts due to delays in replenishment from their factories to the distribution centers. These stockouts had a significant impact on customer satisfaction, sales revenue, and overall supply chain efficiency.

The delay in replenishment from the factories to the distribution centers was caused by a combination of factors, including suboptimal transportation planning, inefficient coordination between manufacturing and logistics teams, and inadequate visibility into inventory levels at each location. These challenges led to inadequate stock levels at the distribution centers, resulting in stockouts and missed sales opportunities.

Solutions: By implementing advanced simulation models, and supply chain optimization techniques, Quantzig helped the manufacturer enhance revenue growth management in CPG, and streamline their inventory management, reducing stockouts and ensuring timely replenishment, leading to improved customer satisfaction and increased operational efficiency.

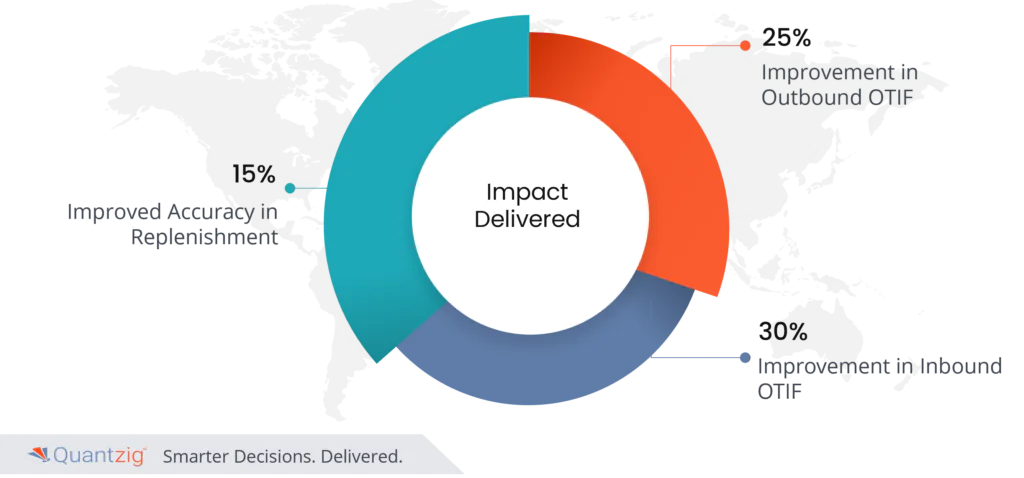

Impact Delivered

All of the above initiatives resulted in:

Industry Overview

- The Consumer-Packaged Goods (CPG) manufacturing industry is a highly competitive and dynamic sector, characterized by large-scale production, extensive distribution network, and continuous innovation.

- The industry is significant both in terms of its contribution to the economy and its impact on consumer lives. It is a major employer, providing jobs to millions of individuals across various roles, from production line workers to marketing professionals.

- On-Time and in-full (OTIF) maximization is crucial in the CPG industry to ensure the timely delivery of products to retailers and meet consumer demands. Data Analytics can help identify bottlenecks in the supply chain, track performance metrics, and revenue growth management in CPG, enhance proactive measures, and improve OTIF rates.

About the Client

- The client’s extensive manufacturing operations encompassed over 30 sites worldwide, contributing to their status as a prominent CPG manufacturer based in the USA. Similarly, their distribution network spanned across 50+ centers globally, ensuring efficient product delivery to diverse markets.

- To manage their complex logistics network, the client relied on a combination of in-house logistics operations and third-party logistics (3PL) providers. This hybrid approach allowed them to leverage both internal expertise and external resources to meet customer demands effectively.

- However, due to the combination of in-house and 3PL logistics, and the diverse production sites, gaining visibility into the entire flow of their supply chain became increasingly challenging for the client. It was essential for them to have a clear understanding of the movement of goods from production to distribution to ensure timely and efficient order fulfillment, and revenue growth management in CPG.

- The lack of comprehensive visibility posed significant obstacles for the client in terms of tracking inventory levels, optimizing transportation routes, and identifying potential bottlenecks or inefficiencies in their operations.

Challenges

- The client’s high order volume, surpassing 50 million, along with an average of 20,000 orders per day, presented a significant logistical challenge. These orders originated from geographically dispersed locations, each requiring different routing configurations based on their respective destinations.

- The complexity of the OTIF (On-Time-In-Full) delivery problem intensified as the client had to navigate diverse transportation networks and optimize routes to ensure timely and complete deliveries. The sheer scale and intricacy of managing such a vast number of orders further amplified the need for an efficient and streamlined logistics solution.

- With multiple orders being processed simultaneously and distributed across various locations, it became critical for the client to minimize delivery delays and avoid order fulfillment errors. On-Time-In-Full performance was crucial to enhance revenue growth management in CPG, retaining business relationships, and upholding the client’s reputation in the CPG industry.

- The main challenge faced by the client was the aggregation of data from their various 3PL vendors and outsourced manufacturing partners. This data was typically communicated in the form of Excel spreadsheets and emails, adding to the complexity of the task. The reliance on multiple sources and formats made the data collection process time-consuming and prone to errors.

- The lack of standardized data posed a challenge in effectively consolidating and reconciling the information received from different vendors and partners. This hindered the client’s ability to gain a comprehensive and accurate view of their supply chain performance.

- Furthermore, the reliance on manual data entry and processing increased the risk of data inconsistencies and delays, impacting the client’s ability to make timely decisions, enhance revenue growth management in CPG, and respond to market dynamics effectively.

Solutions

- With the data systematized and readily available, Quantzig proceeded to develop advanced simulation models. These models were designed to analyze the data and identify potential scenarios that had a higher probability of leading to OTIF failure.

- The simulation models employed sophisticated algorithms to simulate various supply chain scenarios, taking into account factors such as transportation routes, order volume, delivery timelines, and vendor performance. By running these simulations, the models could accurately assess the risks associated with each scenario and prioritize them based on the likelihood of OTIF failure.

- This approach enabled the client to proactively identify potential bottlenecks, operational inefficiencies, or external factors that could impact their ability to meet OTIF requirements. Armed with this information, the client could focus their resources and interventions on mitigating the highest-priority scenarios, thereby improving their overall OTIF performance.

- Through comprehensive data analysis, Quantzig identified the critical nodes within the client’s supply chain that were responsible for the maximum number of delays. These nodes included warehouse pickups, inventory replenishment processes, and manufacturing delays.

- Warehouse pickups were identified as a significant bottleneck, as delays in collecting goods from the warehouse impacted on the overall order fulfillment timeline. By pinpointing this node, the client could focus on revenue growth management in CPG, optimizing pickup processes, such as improving scheduling, enhancing coordination with transporters, and implementing efficient loading procedures.