In the fast-paced landscape of pharmaceutical manufacturing, ensuring the optimal performance of equipment is critical for maintaining efficiency and avoiding financial losses. This is where predictive maintenance, leveraging state-of-the-art technologies, becomes indispensable. By employing a data-driven approach, incorporating industrial IoT sensors, analytics platforms, and AI-based solutions, pharmaceutical manufacturers can enhance operational efficiency, minimize unplanned downtime, and achieve peak performance. This case study delves into how our strategic methodologies and digitalization in pharma enabled a pharmaceutical manufacturer to set up a robust predictive maintenance system, utilizing advanced AI and machine learning capabilities to ensure a resilient pharmaceutical value chain.

Table of Contents

Summary

Client Details: A multinational pharmaceutical manufacturer with over $2 billion in revenues.

Challenges: The client faced challenges in maintaining production profit margins due to frequent ad-hoc machine failures across their plant locations. These failures led to costly breakdowns, production losses, and high maintenance costs. The client recognized the need for a proactive approach to reduce failure risks and improve operational efficiency.

Solutions:

Quantzig assisted the client in setting up predictive maintenance using sensor-based Internet of Things (IoT) data. The client installed multiple sensors across their processes, generating millions of data points during each production cycle. However, this valuable data was scattered across various sources, limiting its availability for business analysis.

Quantzig helped integrate the sensor-based data into a central data lake, enabling downstream analysis for risk identification. The team applied models like random forests, Hidden Markov Models (HMM), and neural networks to predict device failure stages and identify the main causes of failure. Interactive dashboards were developed to provide real-time alerts for maintenance schedules, visit updates, warranty expirations, and historical performance deviations.

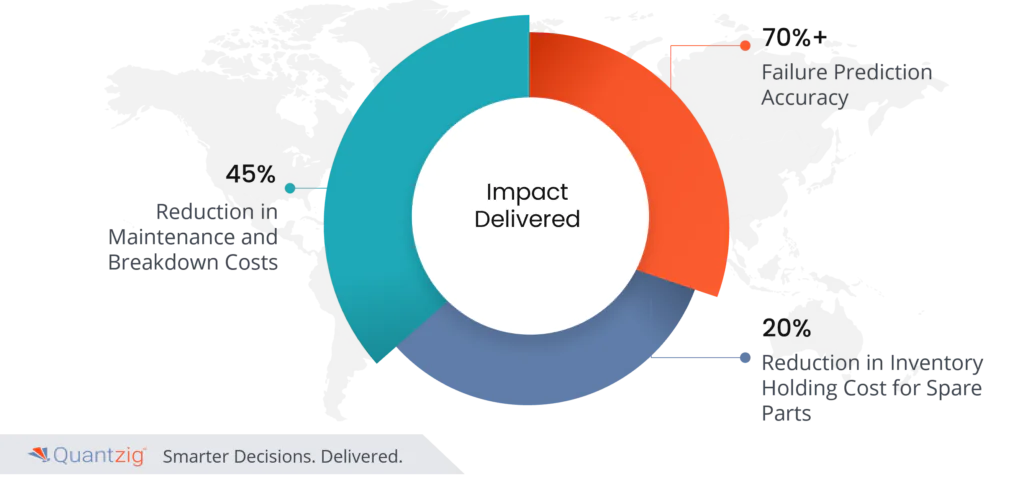

Impact Delivered

All of the above initiatives resulted in:

- 45% Reduction in maintenance and breakdown costs

- 70%+ Failure Prediction Accuracy

- 20% Reduction in inventory holding cost for spare parts

Industry Overview

- The multinational pharmaceutical industry is a crucial sector engaged in the development, manufacturing, and distribution of drugs and pharmaceutical products worldwide. With a focus on research and development, pharmaceutical companies strive to discover innovative treatments for various diseases. The industry is characterized by stringent regulations to ensure safety and efficacy.

- Predictive maintenance models play a significant role in this industry by helping companies optimize equipment performance and minimize the risks of machine failures. By leveraging sensor-based data and advanced analytics techniques, predictive maintenance enables proactive identification of potential equipment issues, reducing downtime, optimizing maintenance schedules, and ensuring uninterrupted production. These results in improved operational efficiency, cost savings, and productivity increase in the pharmaceutical manufacturing process.

The Power of Predictive Maintenance for Pharma

1. Data-Driven Approach and Industrial IoT Sensors:

In the pharmaceutical industry, embracing a data-driven approach and leveraging Industrial IoT sensors play a pivotal role in predictive maintenance for manufacturing equipment. By condition Monitoring functional parameters through these sensors, pharmaceutical companies gain real-time insights into equipment performance, enabling early detection of potential issues and minimizing unplanned downtime.

2. AI-Based Predictive Maintenance and Machine Learning Capabilities:

The adoption of AI-based predictive maintenance, coupled with machine learning capabilities, empowers pharmaceutical manufacturers to optimize the overall productivity of their production and manufacturing operations. By analyzing historical data and patterns, AI-driven systems can predict equipment failures, allowing for proactive asset maintenance and reducing the risk of financial losses associated with unplanned downtime.

Transform your pharmaceutical operations with Quantzig’s advanced predictive maintenance solutions. Elevate reliability, reduce downtime, and stay ahead in Pharma 4.0 – Explore the future of proactive asset management with us. To know more,

Request a free proposal3. Total Productive Maintenance (TPM) and Advanced Data Analytics:

Implementing Total Productive Maintenance (TPM) principles and advanced analytical tools ensure a comprehensive and proactive Time-Based Maintenance Strategy. Routine maintenance activities are optimized, overall productivity is increased, and potential machine failures are mitigated. This strategic combination addresses operational costs, diminished performance, and enhances the pharmaceutical value chain’s resiliency.

4. Purpose-Built Software Platform and Sustainable Competitive Advantage

By deploying a purpose-built software platform for predictive maintenance, pharmaceutical companies can achieve a sustainable competitive advantage. This platform integrates predictive maintenance software, machine learning algorithms, and process modeling knowledge to optimize the maintenance lifecycle. In complex industrial environments, this approach ensures asset performance optimization and supports the pharmaceutical supply chain’s resilience in a digitalized era.

Benefits of Predictive Maintenance in Pharmaceutical industry

1. Enhanced Operational Efficiency:

This solution in the pharmaceutical industry brings about a transformative shift towards enhanced operational efficiency. By leveraging real-time insights from industrial IoT sensors and advanced analytics platforms, pharmaceutical manufacturers can proactively address potential machine failures, reducing unplanned downtime and optimizing overall production and manufacturing operations. This leads to a significant boost in productivity, ensuring the pharmaceutical value chain operates seamlessly.

2. Cost Reduction and Resources Optimization:

One of the primary benefits of this tool is its ability to minimize operational costs through optimized resource utilization. By adopting AI-based predictive maintenance and machine learning algorithms, pharmaceutical companies can strategically allocate maintenance personnel and resources, ensuring routine maintenance activities are performed precisely when needed. This not only reduces unnecessary expenditures but also contributes to the overall efficiency of the pharmaceutical supply chain, fostering a competitive edge in the market.

3. Increased Productivity and Peak Performance:

This tool facilitates increased productivity and peak performance in pharmaceutical manufacturing. By continuously monitoring functional parameters, employing wireless predictive maintenance technologies, and utilizing machine learning capabilities, companies can achieve early detection of potential machine failures. This ensures that equipment operates at its peak performance levels, minimizing production impact, and optimizing overall pharmaceutical production costs.

4. Sustainable Competitive Advantage and pharmaceutical supply chain resiliency:

Adopting a data-driven approach and purpose-built software platforms for predictive maintenance establishes a sustainable competitive advantage and enhanced pharma supply chain resiliency in the pharmaceutical industry. By investing in technology, implementing Total Productive Maintenance (TPM) principles, and embracing industrial digital transformation, pharmaceutical companies enhance asset performance optimization. This not only fortifies the resilience of the pharmaceutical supply chain but also positions the organization for an optimized future in the face of a competitive market and evolving industry trends.

About the Client

- A multinational pharmaceutical manufacturer with more than $2 Billion in revenues was facing challenges in maintaining their production profit margins owing to multiple ad-hoc machine failures from time to time.

- The client sought to implement predictive maintenance as a solution to minimize the impact of ad-hoc machine failures on their production profit margins. This proactive approach aimed to detect potential equipment issues before they led to costly breakdowns.

Challenges

- The installation of multiple sensors across the client’s processes resulted in the generation of a vast amount of data, amounting to millions of data points during each production cycle. However, this valuable data was dispersed across various databases, making it difficult for the client to access and analyze it for business insights. The unavailability of centralized and organized data hindered the client’s ability to perform comprehensive analysis and gain meaningful insights that could drive improvements and optimizations in their production processes. The scattered nature of the data also made it challenging to identify patterns, anomalies, and potential correlations that could help in predicting machine failures or optimizing maintenance schedules.

- Due to the dispersed data and unavailability of centralized analytics, the client was unable to receive timely sensor-based alerts for potential machine failures. This lack of real-time alerts meant that the client often experienced machine breakdowns without prior warning, leading to product disruptions and significant operational costs. The absence of proactive notifications prevented the client from taking preventive action and addressing potential issues before they escalated into major breakdowns. Consequently, the client incurred high costs associated with production losses due to unplanned downtime and increased maintenance expenses to repair and restore the machines. The frequent machine breakdowns not only impacted on the client’s profitability but also strained their resources, as maintenance teams had to allocate significant time and effort to handle the ad-hoc failures. By implementing predictive maintenance, the client aimed to rectify this issue by leveraging the sensor data and receiving timely alerts for potential machine failures.

- Further, the frequent machine breakdowns and production losses had a direct impact on the client’s ability to meet delivery deadlines, resulting in delayed shipments to their customers. The delays in deliveries not only affected the client’s reputation but also led to dissatisfaction among their customers, who were expecting timely and reliable service. Unhappy customers could potentially result in lost business opportunities, as they may seek alternative suppliers or switch to competitors who can deliver products on time.

Solutions

- With the assistance of Quantzig, the client successfully integrated all relevant sensor-based data into a central data lake. This consolidation of data allowed for easier accessibility and streamlined analysis, as all the necessary information was now available in one centralized location. The central data lake became a valuable resource for downstream analysis, enabling the client to perform in-depth assessments and identify potential risks associated with machine failures. The ability to analyze the data systematically empowered them to make informed decisions and take proactive measures to mitigate risks before they caused significant disruptions or breakdowns.

- Further, we applied models such as random forests, HMM, and neural networks to predict the Device failure stage-initial failure, random failure, wear-out failure, and Period of breakdown (date), and to help identify the main causes of failure. The application of random forests, HMM, and neural networks helped in improving the accuracy and reliability of failure predictions, enabling the client to take proactive actions to mitigate risks and optimize their maintenance strategies. Overall, the use of these predictive maintenance models enabled them to gain valuable insights into the device failure process, enhance their decision-making processes, and improve the overall performance and reliability of their production equipment running.

- For ongoing tracking, we helped build interactive dashboards to help provide real-time alerts for maintenance schedules, visit updates, warranty expirations, and historical performance deviations. By consolidating and visualizing this information in a user-friendly interface, the interactive dashboards allowed them to monitor and track crucial maintenance activities in real time. Overall, the interactive dashboards provided a centralized and accessible platform for monitoring, analyzing, and optimizing maintenance-related activities, contributing to improved operational efficiency and reduced risks of machine failures.

How Quantzig helps in Achieving Predictive Maintenance in pharma?

1. Advanced Analytics and Machine Learning Capabilities:

Quantzig empowers pharmaceutical companies by integrating state-of-the-art technologies, including advanced data analytics and machine learning capabilities, into their predictive maintenance strategies. This involves leveraging predictive maintenance software, industrial IoT sensors, and purpose-built software platforms to analyze complex data sets and develop machine learning algorithms. By doing so, our team facilitates early detection of potential machine failures and ensures asset performance optimization.

2. Proactive Asset Maintenance and Total Productive Maintenance (TPM):

Our team takes a proactive approach to asset maintenance, aligning with Total Productive Maintenance (TPM) principles. This involves optimizing routine maintenance activities through strategic methodologies and investing in technology. By utilizing real-time insights from Industrial IoT sensors and implementing a data-driven decision-making process, we enhance overall productivity, reduces unplanned downtime, and fortifies the pharmaceutical supply chain’s resiliency.

3. Comprehensive Analysis of Operational Costs and Productivity:

Quantzig conducts a thorough analysis of operational costs and productivity in the pharmaceutical value chain network. This includes evaluating production impact, production costs, and the overall efficiency of manufacturing equipment. By optimizing resources and implementing wireless predictive maintenance technologies, our team helps pharmaceutical companies achieve increased productivity, peak performance, and a competitive edge in the market.

4. Tailored Solutions for Sustainable Competitive Advantage:

Our experts provide tailored solutions that contribute to a sustainable competitive advantage for pharmaceutical manufacturers. Through industrial digital transformation and a focus on the pharmaceutical supply chain’s resiliency, we ensure that its solutions align with the optimized future of the industry. By considering temperature data, visual inspection results, and the maintenance lifecycle, Quantzig facilitates a purpose-built software platform that meets the unique needs of pharmaceutical companies, positioning them for success in a competitive market.

In conclusion, our tailored predictive maintenance solution not only revolutionized routine maintenance in the pharmaceutical manufacturing process but also showcased the transformative power of industrial digital transformation. By strategically leveraging cutting-edge technologies and embracing a proactive approach, our client experienced increased productivity, operational efficiency, and cost savings. As the pharmaceutical industry navigates a competitive market, our predictive maintenance implementation proved instrumental in ensuring a resilient and optimized future for our client’s production and manufacturing operations.