Effective inventory management is essential for success in the food and beverage industry. It requires striking a delicate balance – maintaining sufficient stock to satisfy customer demand without accumulating excessive inventory that ties up capital and leads to spoilage. Given the unique challenges posed by perishable food products, it is crucial to account for these factors when developing a food and beverage inventory management strategy. This article will outline ten key strategies and best practices for optimizing inventory management in the food and beverage sector.

Book a demo to experience the meaningful insights we derive from data through our analytical tools and platform capabilities. Schedule a demo today!

Request a Free DemoTable of Contents

What Is Inventory Management?

Inventory management is the process of overseeing and controlling the ordering, storage, and use of components that a company will use in the production of the items it will sell. It is a critical function that ensures a company has the right amount of inventory to meet customer demand while minimizing excess inventory and costs.

What is F & B Inventory Management?

F&B (Food and Beverage) Inventory Management is the process of overseeing and controlling the ordering, storage, and use of food and beverage products within a company. It involves strategies to maintain the right balance of inventory to meet customer demand while minimizing waste and spoilage due to the perishable nature of these goods. Effective F&B inventory management requires techniques like batch tracking, expiration date monitoring, demand forecasting, and optimizing storage conditions to ensure product freshness and availability.

Best Practices for Inventory Management in the Food and Beverage Industry

1. Advanced Inventory Control with Finale Inventory:

Implementing state-of-the-art warehouse management software like Finale Inventory is essential for achieving advanced control, as it enables real-time tracking, enhances order accuracy, and reduces excessive inventory levels. By leveraging Finale Inventory, food and beverage businesses can effectively manage the complexities of perishable products and imported foods while ensuring compliance with stringent food safety regulations, such as the Food Safety Modernization Act (FSMA).

2. Demand Forecasting for Optimal Inventory Levels:

- Accurate demand forecasting is crucial for maintaining optimal inventory levels and timely availability of products.

- This approach not only minimizes the risk of profit losses associated with excessive inventory but also supports robust quality control processes.

- By optimizing the levels, companies can improve customer satisfaction and ensure reliable delivery schedules, ultimately fostering stronger relationships with suppliers.

3. First In, First Out (FIFO) Method for Perishable Products:

In the food and beverage industry, the First In, First Out (FIFO) method is a best practice for managing perishable products, ensuring that the oldest inventory is used first to reduce the risk of spoilage and waste. Quantzig’s commitment to continuous improvement and adaptation includes promoting FIFO to enhance inventory accuracy. Regular inventory audits, aligned with industry best practices, further strengthen operational efficiency and contribute to improved customer satisfaction.

4. Data-Driven Decision-Making with Key Performance Indicators (KPIs):

- Quantzig emphasizes the importance of monitoring Key Performance Indicators (KPIs) to evaluating the effectiveness of food and beverage inventory management efforts. Metrics like the inventory turnover ratio and gross margin return on inventory investment (GMROI) provide valuable insights into inventory performance.

- This data-driven approach enables companies to make informed decisions, optimize inventory levels, and drive profitability. In an industry shaped by changing market dynamics, internal performance data, and new technologies, leveraging KPIs ensures a competitive edge and supports continuous improvement in inventory management strategies.

Also Read: Maximizing Marketing Budgets with Campaign ROI Analysis

Get started with your complimentary trial today and delve into our platform without any obligations. Explore our wide range of customized, consumption driven analytical solutions services built across the analytical maturity levels.

Start your Free Trial TodayWhy Inventory Management Matters?

1. Compliance with Food Safety Regulations and FSMA:

It is essential in ensuring compliance with stringent food safety regulations, including the Food Safety Modernization Act (FSMA). Utilizing warehouse management software facilitates real-time tracking and adherence to regulatory changes. This not only mitigates the risk of profit losses due to non-compliance but also establishes a competitive edge by demonstrating a commitment to food safety standards and regulations.

2. Precision in Order Accuracy and Delivery Schedules:

In the food and beverage industry, order accuracy and timely delivery schedules are paramount for customer satisfaction. By maintaining strong supplier relationships, businesses can minimize inventory levels and enhance the precision of order fulfillment. This not only optimizes inventory levels but also contributes to improved customer satisfaction, solidifying the company’s reputation in the market.

3. Optimal Inventory Levels through Accurate Demand Forecasting:

Accurate demand forecasting is a cornerstone of successful food and beverage inventory management. By leveraging data-driven insights, businesses can anticipate market trends and consumer preferences, minimizing excessive inventory levels. This practice not only ensures the timely availability of products but also aligns with industry best practices, supporting robust quality control processes and contributing to ongoing profitability.

4. Continuous Improvement for Adaptation to Market Dynamics:

It is an ongoing process that requires continuous improvement and adaptation to changing market dynamics. By monitoring Key Performance Indicators (KPIs) like the inventory turnover ratio and gross margin return on inventory investment (GMROI), businesses gain valuable insights into their performance. Embracing new technologies and internal performance data allows for data-driven decision-making, providing a competitive edge in the industry and facilitating sustainable company growth.

Tips for Effective F&B Inventory Management

1. Accurate Demand Forecasting

- Analyze historical sales data, seasonal trends, and market conditions to accurately predict future demand

- Use techniques like moving averages, weighted averages, or advanced statistical models for forecasting

2. Establish Reorder Points and Safety Stock

- Determine reorder points based on factors like lead time, demand variability, and desired service level

- Maintain appropriate safety stock levels to absorb unexpected fluctuations in demand or supply

3. Leverage Technology and Automation

- Utilize inventory management software to track stock levels, monitor sales trends, and generate reports

- Implement barcode scanners, RFID, and IoT sensors for real-time inventory visibility and accuracy

4. Categorize Inventory Using ABC Analysis

- Categorize inventory items into A, B, and C classes based on value and usage

- Focus inventory management efforts on the most critical “A” items

5. Practice FIFO (First-In, First-Out)

- Ensure older stock is sold or used before newer stock to minimize waste and spoilage

- Assign lot numbers and expiration dates to batches for traceability

6. Conduct Regular Inventory Audits

- Physically count inventory and reconcile with system records to identify discrepancies

- Use audits to detect issues like theft, misplacement, or data entry errors

7. Monitor Key Performance Indicators (KPIs)

- Track metrics like inventory turnover ratio, GMROI, and stockout rate

- Use KPIs to evaluate inventory management effectiveness and identify areas for improvement

8. Continuously Improve and Adapt

- Regularly review and adjust inventory strategies based on customer feedback, market trends, and internal data

- Stay updated on new technologies, best practices, and regulatory changes impacting the industry

By implementing these best practices, food and beverage businesses can optimize inventory management, reduce waste and spoilage, enhance customer satisfaction, and drive operational efficiency.

Quantzig’s Expertise in F&B Inventory Management Solution for a Leading Food & Beverage Manufacturer

| Category | Details |

|---|---|

| Client | Leading food & beverage manufacturer with global presence |

| Client Profile | – Multiple manufacturing sites across Southeast Asian nations – Served diverse client base of over 200 customers, predominantly from North America and Western Europe |

| Challenges | – Effective management across global supply chain – Precise inventory management to meet customer expectations while minimizing stockouts and expiry – Lack of accurate demand forecasting and production planning capabilities – Excess inventory levels, poor rotation practices, and increased expiry rates |

| Solutions | – Developed robust mechanism to identify exact inventory required at each warehouse for each SKU – Raised flags based on available shelf space for SKUs already present in the warehouse – Identified unsellable inventory at specific warehouses and implemented cost-effective solution to translocate items to other warehouses |

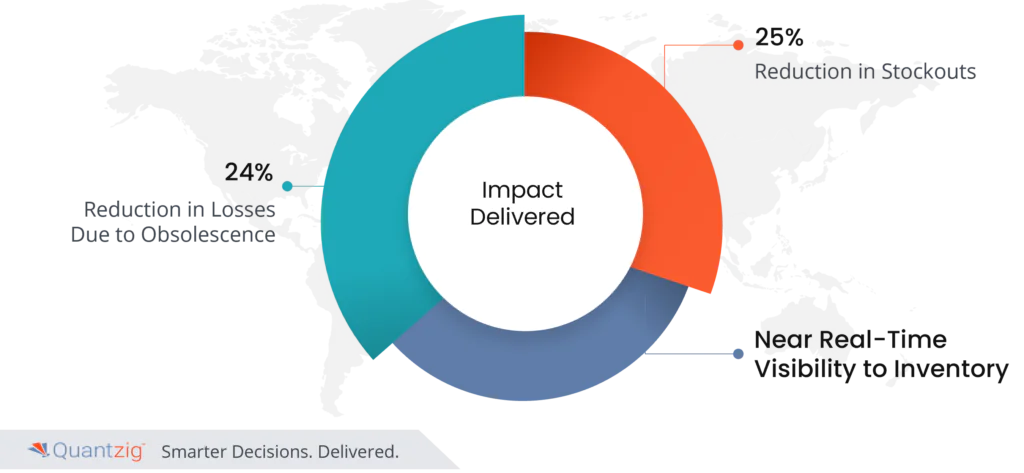

| Impact Delivered | – 24% reduction in losses due to obsolescence – 25% reduction in stockouts – Near real-time visibility to inventory |

Industry Overview

The global food and beverage manufacturing industry is a dynamic and competitive sector that continuously evolves to meet the changing needs and preferences of consumers. This industry is a significant contributor to the global economy, with a substantial market size. With a focus on innovation, sustainability, and regulatory compliance, industry players strive to provide safe, high-quality, and diverse food and beverage products to consumers worldwide. The industry leverages technology to enhance efficiency, improve production processes, and meet quality standards. Automation, data analytics, robotics, and artificial intelligence are increasingly utilized in manufacturing operations, supply chain management, and quality control processes.

About the Client

The leading Food & Beverage manufacturer operates over 50 manufacturing sites, strategically distributed across Southeast Asian nations.With a client base of over 200, their products cater to global markets, primarily generating demand from North America and Western Europe. However, the concentration of demand from North America and Western Europe posed inventory management challenges, leading to a higher risk of stock expiry.

Due to the geographical distribution and demand concentration, the company faced challenges in managing stock expiry values. The extended supply chain and longer transit times increased the risk of products reaching their expiration dates before reaching customers.

F&B Inventory Management Challenges Faced by the Client

- In the post-pandemic period, the company faced a merchandise dilution rate of 10-12%, attributed to various factors such as expiration, packaging issues, and handling problems. This dilution created a cycle where certain warehouses became overstocked with diluted products, while others experienced understocking.

- The inefficiencies in managing merchandise quality and handling resulted in lost revenue and disrupted inventory levels, necessitating improvements in quality control, packaging, and handling processes to minimize dilution and optimize stock levels across warehouses.

- The seasonal nature of the demand in North America and supply disruptions in Southeast Asia had created serious challenges in terms of maintaining supply chain agility and developing a management strategy.

- The fluctuating demand patterns, driven by seasonal factors such as holidays or specific consumption trends, required the manufacturer to anticipate and respond to rapid shifts in customer preferences and order volumes. This necessitated a flexible supply chain that could quickly adjust production levels, allocation, and distribution to meet changing demands.

- The supply disruptions in Southeast Asia, which could be caused by natural disasters, geopolitical events, or transportation challenges, further complicated the supply chain management process. These disruptions affected the availability of raw materials, production capacities, and transit times, leading to potential delays or disruptions in the timely replenishment of inventory.

F&B Inventory Management Solutions Offered by Quantzig

- To further optimize f&b inventory management system, our team developed a mechanism to raise flags based on the available shelf space for SKUs already present in the warehouse. By leveraging warehouse management systems, our solution monitored the shelf occupancy of each SKU in real time.

- When the available shelf space reached a predetermined threshold, the mechanism would raise flags or trigger alerts, signaling the need for replenishment or reorganization of the inventory. This proactive approach ensured that the warehouse remained well-organized, preventing overcrowding or inefficient use of space that could lead to difficulties in locating products or potential damage to items.

- We further built the capacity to identify the inventory which cannot be sold at a given warehouse and identified a cost-effective way to translocate them into other warehouses. By analyzing factors such as demand patterns, market conditions, and product life cycles, our solution could determine which inventory items were unlikely to be sold at their current location.

- Based on this analysis, we recommended suitable alternative warehouses where the inventory could be more effectively utilized or where demand for those specific items was higher. This allowed for a strategic redistribution of inventory to maximize sales opportunities and minimize potential losses due to product obsolescence.

- The implementation of this capacity provided the manufacturer with enhanced flexibility and agility in managing their inventory across different locations. It enabled them to proactively address sales limitations at specific warehouses, reduce the risk of product obsolescence, and improve overall supply chain efficiency.

Impact Delivered

All of the above initiatives resulted in:

- 24% reduction in losses due to obsolescence

- 25% reduction in stockouts

- Near real-time visibility to inventory

Also Read: Track Business Progress with Marketing Analytics Dashboard

Experience the advantages firsthand by testing a customized complimentary pilot designed to address your specific requirements. Pilot studies are non-committal in nature.

Request a Free PilotConclusion

Improving inventory management in the food and beverage industry involves navigating challenges like stockouts and fluctuating customer demand. By leveraging technologies for accurate demand forecasting and maintaining optimal inventory levels, businesses can enhance order management and control. Implementing best practices such as regular inventory audits and strategic use of safety stock supports efficient operations. Quantzig’s solutions integrate historical sales data and market dynamics to optimize Days Sales of Inventory (DSI), ensuring streamlined inventory management strategies that address industry-specific challenges. This holistic approach enhances overall efficiency and responsiveness, crucial for sustained success in the competitive food and beverage market.