Author: Associate Vice President, Analytics and Data Strategy, Quantzig.

In the Consumer-Packaged Goods (CPG) industry, maintaining optimal inventory control is paramount to success. At Quantzig, we partnered with a thriving CPG client to revolutionize their inventory management practices, addressing challenges like stockouts, out-of-stock (OOS) events, and their impact on customer orders, satisfaction, and retention. Through meticulous analysis, strategic interventions, and the seamless integration of NetSuite Inventory Management Systems Software, we showcased how our tailored solutions transcended traditional inventory management practices, paving the way for optimized storage costs, minimized product obsolescence, and simulated product recalls with precision and confidence.

Book a demo to experience the meaningful insights we derive from data through our analytical tools and platform capabilities. Schedule a demo today!

Request a Free DemoTable of Contents

What is CPG Inventory Management?

CPG (Consumer Packaged Goods) inventory management is the process of overseeing and controlling the flow of goods from acquisition to sale for consumer-packaged goods companies. It involves monitoring inventory levels, forecasting demand, and ensuring sufficient stock is available to meet customer needs while minimizing excess inventory and associated costs.

Quantzig’s Expertise in CPG Inventory Management Solution for a Leading CPG Industry

| Category | Details |

|---|---|

| Client Overview | Our recent client was a leading player in the FMCG and CPG industry, headquartered in the USA. With a robust workforce of 6000 talented employees and a commitment to innovation and customer satisfaction, they redefine industry standards and create exceptional products that captivate the market. |

| Challenges Faced by the Client | Our visionary client embarked on the challenge of minimizing average stock and eliminating stockouts across multiple warehouses, unlocking opportunities through strategic material transfers. However, they faced the daunting hurdles of inventory imbalance and inefficient stock movements, hampering their quest for seamless operations and customer satisfaction. |

| Solutions Offered by Quantzig | Our cutting-edge solution made a significant impact on their business operations by providing them with a dynamic and proactive approach to supply chain management. Our team dynamically identified forecasted versus actual demand, forecasted deviations at the customer level, and automatically created a redistribution plan based on likely stockout scenarios. This solution empowered their logistics team to proactively prevent stockouts and optimize inventory allocation, resulting in improved operational efficiency and customer satisfaction. |

| Key Focus Areas | Minimizing average stock, and eliminating stockouts across multiple warehouses |

| Impact Delivered | A remarkable 40% reduction in stockout instances, a commendable 3% reduction in overall stock-on-hand, enhanced operational efficiency, contributed to improved inventory turnover rates, and reduced carrying costs. |

About the Client

- We recently engaged with a prominent leading player in the FMCG and CPG industry, headquartered in the United States. With an eye for innovation and a commitment to excellence, they have firmly established themselves as a market leader.

- Boasting a diverse range of high-quality products that cater to the ever-evolving needs of consumers, our client stands at the forefront of the industry. Their extensive portfolio is designed to enrich lives and enhance everyday experiences, from household essentials to personal care items.

- With a workforce of over 6000 talented individuals, they have a highly passionate team that fuels their long-term business success. Drawing on a wealth of expertise and a drive for continuous improvement, they consistently deliver products that exceed customer expectations.

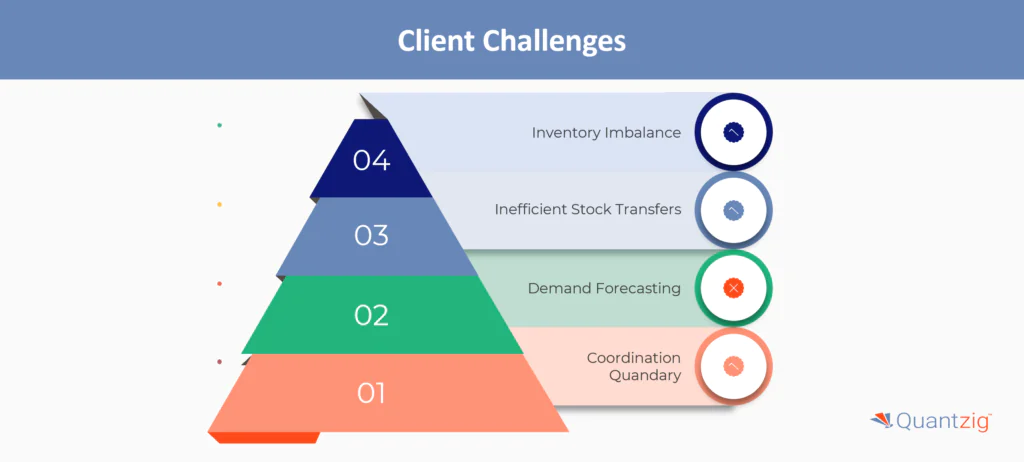

Challenges Faced by the Client

- In their pursuit of operational excellence, the client in the FMCG and CPG industry encountered a crucial challenge: optimizing stock levels across multiple warehouses while minimizing stockouts. Acknowledging the immense potential for improvement, they set out to tackle this obstacle head-on.

- Challenge 1: Inventory Imbalance: With warehouses scattered across various locations, they grappled with an uneven distribution of stock. Some warehouses were overburdened with excess inventory, while others faced constant stockouts, leading to customer dissatisfaction and missed sales opportunities.

- Challenge 2: Inefficient Stock Transfers: The company realized the need for strategic material transfers between warehouses. However, existing processes proved inefficient, causing delays, errors, and increased costs. Ensuring seamless and timely transfers while minimizing disruptions became a complex puzzle to solve.

- Challenge 3: Demand Forecasting: Insufficient demand forecasting hindered their ability to plan and allocate resources effectively, resulting in suboptimal stock levels and missed revenue potential. Without real-time data and analytics, they struggled to identify areas of improvement, proactively respond to market shifts, and optimize their inventory management.

- Challenge 4: Coordination Quandary: Orchestrating seamless coordination across multiple warehouses became a Herculean task, as the client endeavored to align teams, streamline processes, and synchronize their supply chain symphony. With unwavering resolve and a thirst for innovation, our client is set to conquer these challenges. By leveraging innovative technologies, data-driven insights, and cross-functional collaboration, they are poised to transform their warehouse operations and achieve their goal of optimized stock levels and reduced stockouts. Together, we embarked on this exciting journey toward a more efficient and streamlined future.

Solutions Offered by Quantzig

- Our groundbreaking solution made a significant impact on the client’s operations by providing them with a dynamic and proactive approach to supply chain management. By dynamically identifying and analyzing forecasted versus actual demand at the customer level, we provided them with invaluable insights into their inventory management.

- Our ability to forecast deviations for each customer was instrumental in mitigating stockouts. By identifying likely scenarios of stockouts in the next 2-3 weeks, we enabled the retail client to take timely actions and prevent disruptions in their supply chain. This foresight is invaluable in maintaining high levels of customer satisfaction.

- The highlight of Quantzig’s contribution lies in their automated creation of a comprehensive plan for warehouse-to-warehouse transfers. By carefully balancing the business benefit against the logistics costs, we provided the client with a dynamic redistribution planner that guided the logistics team every week. This planner facilitated strategic decision-making, optimizing inventory allocation and reducing the risk of stockouts.

- Our solution revolutionized the client’s supply chain management, bringing efficiency, agility, and cost-effectiveness to their operations. Our expertise and eye for detail helped the company stay ahead of demand fluctuations, minimize disruptions, and enhance customer satisfaction.

Impact Delivered from Quantzig’s CPG Inventory Management Solution

- 40% reduction in stockout instances, improving inventory availability and customer satisfaction

- 3% reduction in overall stock-on-hand, optimizing resource utilization and minimizing storage costs

- Optimized inventory allocation across the supply chain, enhancing operational efficiency and improving inventory turnover rates

The holistic approach to inventory management, combined with the innovative solutions implemented, yielded tangible benefits for the client. These outcomes not only underscored the success of the collaborative efforts but also positioned the client for sustained growth and competitiveness in the ever-evolving Consumer Packaged Goods (CPG) industry.

Also Read: Maximizing Marketing Budgets with Campaign ROI Analysis

Get started with your complimentary trial today and delve into our platform without any obligations. Explore our wide range of customized, consumption driven analytical solutions services built across the analytical maturity levels.

Start your Free Trial TodayWhat are the Causes of Inventory Stockouts?

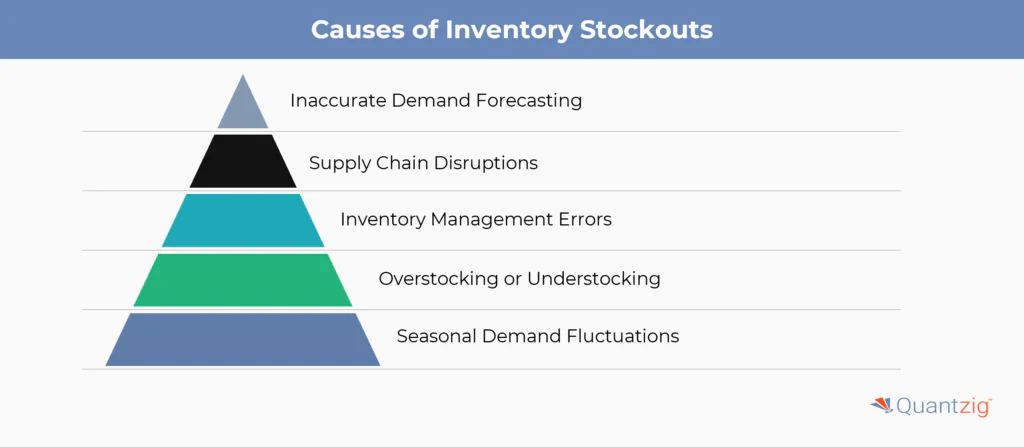

Stockouts, or out-of-stock (OOS) events, can be caused by various factors within the supply chain and inventory management processes. Some common causes of stockouts include:

- Inaccurate Demand Forecasting: Incorrect predictions of customer demand can lead to underestimation of inventory needs, resulting in stockouts when customer orders exceed available stock.

- Supply Chain Disruptions: Any disruptions in the supply chain, such as delays in production, transportation issues, or unexpected supplier shortages, can lead to stockouts by interrupting the flow of goods to the point of sale.

- Inventory Management Errors: Mistakes in inventory tracking, data entry errors, or miscommunication between different departments can result in discrepancies between actual and recorded inventory levels, leading to stockouts.

- Overstocking or Understocking: Poor inventory management practices, such as maintaining excessively high or low stock levels, can result in stockouts. Overstocking ties up capital and storage space, while understocking leads to unfulfilled customer demand.

- Seasonal Demand Fluctuations: Failure to anticipate and adequately prepare for seasonal fluctuations in demand can lead to stockouts when demand exceeds available inventory during peak periods.

Also Read: Track Business Progress with Marketing Analytics Dashboard

Experience the advantages firsthand by testing a customized complimentary pilot designed to address your specific requirements. Pilot studies are non-committal in nature.

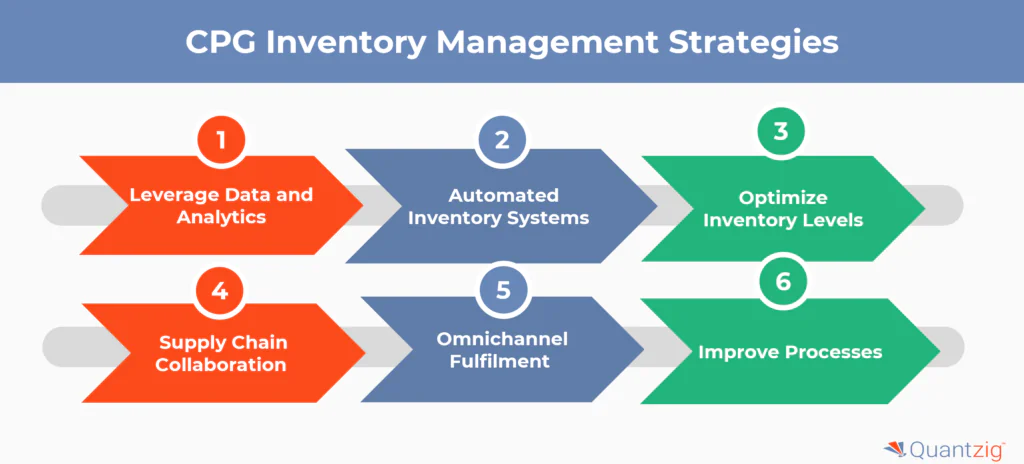

Request a Free PilotWhat are the Effective CPG Inventory Management Strategies?

1. Leverage Data and Analytics

- Utilize advanced analytics and forecasting models to accurately predict demand and optimize inventory levels

- Collect and analyze data from various sources to gain end-to-end supply chain visibility

- Leverage real-time inventory tracking and monitoring to identify trends and respond quickly to changes

2. Implement Automated Inventory Systems

- Invest in enterprise resource planning (ERP) or inventory management software to streamline processes

- Automate replenishment orders and inventory allocation based on demand forecasts

- Integrate systems across the supply chain for seamless data flow and decision-making

3. Optimize Inventory Levels

- Maintain optimal safety stock to buffer against demand spikes and supply chain disruptions

- Regularly review and adjust inventory policies to align with changing market conditions

- Identify and minimize slow-moving or obsolete inventory to free up working capital

4. Enhance Supply Chain Collaboration

- Foster strong partnerships with suppliers, logistics providers, and retailers

- Share demand forecasts and inventory data to enable synchronized planning and execution

- Leverage vendor-managed inventory (VMI) programs to optimize inventory across the supply chain

5. Leverage Omnichannel Fulfillment

- Implement omnichannel strategies to fulfill orders from the most optimal inventory location

- Utilize cross-docking, drop-shipping, and other techniques to reduce inventory holding costs

- Provide customers with real-time inventory visibility and flexible fulfillment options

6. Continuously Improve Processes

- Regularly review and refine inventory management practices based on performance metrics

- Invest in employee training and development to build inventory management expertise

- Adopt a culture of continuous improvement to stay agile and responsive to market changes

By implementing these effective CPG inventory management strategies, companies can enhance operational efficiency, improve customer satisfaction, and drive sustainable growth in the dynamic consumer packaged goods industry.

How Can Quantzig Help Your Business with CPG Inventory Management?

Effective inventory management is crucial for maintaining a competitive edge in the Consumer Packaged Goods (CPG) sector. Quantzig offers advanced analytics solutions designed to optimize every facet of your supply chain. With a focus on demand forecasting and inventory control, Quantzig helps businesses balance supply and demand, minimize excess stock, and streamline operations.

- Quantzig can help your business with CPG inventory management by providing advanced analytics solutions that enhance various aspects of the supply chain.

- Their expertise in demand forecasting and accurate forecasting enables businesses to optimize inventory levels of raw goods and finished goods, ensuring a balanced supply that meets consumer demand while minimizing excess stock.

- Quantzig’s tools also improve inventory turnover rates, helping to reduce holding costs and COGS (cost of goods sold).

- Additionally, Quantzig offers insights into production lead times and aids in effective supplier & co-packer management, ensuring a streamlined and efficient supply chain. Their solutions help maintain appropriate safety stock levels, providing a buffer against supply chain disruptions.

- By leveraging AI and advanced analytics, Quantzig can enhance your overall inventory management strategy, leading to more informed decision-making, reduced operational costs, and improved profitability.

By partnering with Quantzig, you can leverage cutting-edge AI and analytics to refine your inventory management strategy. Our expertise in forecasting, inventory turnover, and supply chain efficiency translates into reduced operational costs, improved profitability, and a more resilient supply chain. With Quantzig’s solutions, you’ll be equipped to make informed decisions and drive success in the dynamic CPG landscape.

Experience the advantages firsthand by testing a customized complimentary pilot designed to address your specific requirements. Pilot studies are non-committal in nature.

Request a Free PilotConclusion

Our innovative solution has revolutionized CPG supply chain management by providing dynamic strategies and insights for forecasting and mitigating stockouts. Automated warehouse transfers optimized inventory allocation, reducing risks and enhancing customer satisfaction. This approach not only addresses current challenges but also sets the stage for continued success with improved forecasting, demand planning, and procurement, demonstrating the transformative power of innovative solutions and strategic partnerships in maintaining a competitive edge.