In the fiercely competitive landscape of the food and beverage (F&B) industry, effective supply chain management is a linchpin for success. The intricate challenges posed by changing consumer preferences, operational costs, and the imperative for product quality and safety demand a sophisticated approach to supply chain analytics. This article explores the transformative role of advanced analytics and new technologies in reshaping the F&B supply chain, emphasizing the critical need for real-time data utilization. Examining the experiences of a leading F&B manufacturer based in Sweden, we delve into the challenges faced, the solutions implemented, and the key takeaways that underscore the significance of supply chain analytics in this dynamic sector.

Table of Contents

Food Supply Chain Analytics for the Industry

The food and beverage industry has always been competitive and is poised to remain a competitive one for many more years. Pressures arising due to changing consumer preferences, ingredient visibility, rising operational costs, production efficiency, and product quality form a complex operating environment for the entire industry as a whole. However, the modern supply chain depends on real-time data to operate efficiently. Survival in the food and beverage industry is not only about visibility and having the agility to capitalize on a rapidly changing market landscape. It’s more about the smart use of advanced analytics and new technologies to create a demand-driven end-to-end digital supply chain management system.

This is why the food and beverage companies today are looking at embracing innovative technologies that help them optimize daily operations and hone profit margins. Admittedly, all of the analytic advancements can be exhaustive, but you can’t afford to be left behind hence we bring to you the top three ways in which advanced analytics and new technologies are transforming the supply chain in the food and beverage industry:

- Big data and supply chain analytics help enhance safety and quality across the global food value chain

- Blockchain technology can be leveraged to develop an invulnerable distribution ledger, that allows businesses to track assets at every stage of the supply chain, creating increased transparency and cost savings

- In a marketplace characterized by narrow profit margins, advanced supply chain analytics can help food and beverage companies to predict future demand and manage stocks efficiently

The client is a leading food and beverage manufacturer based out of Sweden. With a considerable number of manufacturing units spread across Europe, the client was facing predicaments such as lack of visibility through their supply chains, over and understock inventory. Therefore, they approached Quantzig to leverage its expertise in offering supply chain analytics solutions, to track their products through all stages of the supply chain and enhance their approach to supply chain management.

In the current global scenario, food and beverage industry is one of the largest global sectors, and accounts for more than $7 trillion in annual production. Any product needs to be mobilized from the manufacturer or producer to reach the customer who is the end user, and this emphasizes the need for supply chain analysis. Lengthier supply chains will push prices upward and result in more wastage due to ineffective supply chain strategies. Hence, an effective approach to addresses these issues would be based on building a new supply chain strategy that is effective enough to curtail the losses incurred.

Food Supply Chain Analytics Challenges Faced by the Client

With the constantly evolving economic and geopolitical environment, businesses cannot afford to not know their supply chain processes in detail. This holds true for food and beverage companies as they deal with trend-driven products, where in addition to the supply chain hitches, they are consistently exposed to dynamic fluctuations in consumer demands and market trends. Furthermore, such factors lead to unforeseen supply chain interruptions and a shortage of raw materials.

Supply chain analytics experts at Quantzig help leading organizations to analyze dynamic demand patterns and improve supply chain visibility. Get in touch with them right away!

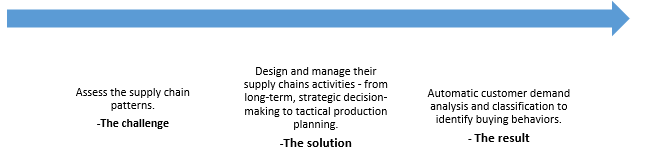

A renowned food and beverage company was facing predicaments in trying to assess their supply chain patterns. The client wanted to use effective supply chain analysis to get a detailed insight on improving their reach in the target areas. In addition, the food and beverage client wanted to utilize technology and leverage the use of supply chain analysis to create a more responsible, thoughtful, and sustainable supply chain strategy, which would help them overcome the current obstacles faced by the food and beverage industry. The supply chain analysis study would help the food and beverage to deliver growth in revenue and keep track of the supply chain network.

Facing a steady decrease in the sales rate and profit margins amid the crisis, the client wanted to streamline its food supply chain structure for improving customer satisfaction, managing inventory, and meeting the existing market demands. The client’s approach to food supply chain management and logistics was unstructured and had a widespread impact on other supply chain processes and overall business growth. The challenges faced by this meat processing company included:

- Inventory stock outs – With rapidly changing customer demands, the meat processing company was facing difficulties in maintaining adequate stocks to meet existing customer demands.

- Inability to meet dynamic market demands – The client lacked a demand forecasting framework that could help them gauge demand and analyze market demand periodically.

- Changing customer needs – Due to the outbreak of COVID-19, customer needs and demands became dynamic and changed every week. In such a scenario, the client’s inability to analyze the current trends and meet customer expectations resulted in severe losses

Revolutionary F&B Supply Chain Management Solutions for the Client

Facing the need to implement food supply chain analysis a food and beverage industry player approached Quantzig to leverage its analytic expertise and gain control over its inventory to keep food distribution safe and efficient. Quantzig’s supply chain analytics solutions offered personalized recommendations to help the food and beverage industry player achieve their business goals. The analytics solution helped them solve several complex decisions with millions of decision variables, restrictions, and trade-offs. The enhanced supply chain analytics capability helped reveal previously unavailable insights into a slow-moving and obsolete inventory, generating about $8M within three months.

Phase 1

The first phase of this supply chain analytics engagement revolved around supply chain risk analysis. In this phase, our supply chain analytics experts helped the client to gain insights into historic supply chain information by region, vendor, and product hierarchies. The extracted data was then contextually juxtaposed with external risk and cost factors. This, in turn, empowered the client’s sourcing team to make better supply chain decisions.

Phase 2

In the second phase of this engagement, the supply chain analytics experts developed a customized dashboard to help the client track and control inventory in the warehouse. The use of advanced analytics dashboards empowered the food and beverage manufacturer to precisely track and monitor supplier performance. Furthermore, this helped the client’s sourcing team to drill down to the root cause of performance inadequacies.

Phase 3

The final phase in the supply chain analytics engagement focused on improving supply chain visibility. Quantzig’ supply chain analytics experts helped the client to gain real-time visibility into their supply chain processes and identify potential risks that could impact their ability to deliver the right product at the right time.

By utilizing Quantzig’s supply chain analysis solution, the food and beverage client could better design and manage their supply chain activities – from long-term, strategic decision-making to tactical production planning. Quantzig’s supply chain modeling methodology enabled the food and beverage client to reduce the overall cost, cut down risks, and edge out the competition. It also helped them gain better visibility into their current supply chain network and helped them manage their resources accordingly.

The experts at Quantzig analyzed the client’s historical sales data to predict the meat market’s seasonality and highest sales records. The analytics experts were also able to identify the forces which were driving the market demand for meat products in the US. They also analyzed the client’s competitors to understand the top categories of meat that were majorly in demand across North America. The demand forecasting exercise done by Quantzig’s food supply chain analytics experts helped the client to accurately predict the upcoming demand and meet customer’s expectations. It even helped the client to allocate their budget and resources effectively in order to better manage the supply chain.

By leveraging Quantzig’s food supply chain analytics solutions the meat processing company was able to:

- Optimize supply chain operations

- Enhance transportation processes

- Replenish inventory stocks beforehand

- Improve the efficiency of their production cycle

- Improve the agility of the food supply chain

Key-Takeaways of F&B Supply Chain Management

By leveraging food supply chain analysis and implementing an end-to-end supply chain analysis the food and beverage industry player was better positioned to identify the key opportunities for bringing about improvements in profit margins and business growth. Supply chain analytics also enabled the food and beverage company to aggregate data to develop dashboards and gain actionable insights. This not only helped them optimize their supply chain operations but also enabled them to enhance operational efficiency by combining descriptive and predictive data sets to regulate the consequences of different choices of action.

With the help of customized analytics dashboards, the client gained detailed insights into their inventory levels, order status, and market demand in addition to supply chain processes. By gaining in-depth supply chain insights, the food and beverage manufacturer was better positioned to tackle supply chain disruption, understock, and overstock situations. The offered solution also helped the client to identify potential savings worth around $3M by reducing distribution costs and enhancing the flexibility of the supply chain.

In conclusion, the implementation of advanced food supply chain analysis and new technologies is revolutionizing the F&B supply chain, ensuring resilience and responsiveness to the industry’s challenges. The experience of the Swedish F&B manufacturer exemplifies the transformative impact of supply chain analytics on inventory management, risk analysis, and overall supply chain visibility. By leveraging Quantzig’s solutions, the client not only overcame specific challenges but also gained a competitive edge in a highly competitive industry. The key takeaways emphasize the critical role of supply chain analytics in optimizing operations, enhancing efficiency, and future-proofing businesses in the dynamic F&B sector.