Table of Contents

Introduction to Supply Chain Data Analytics

Supply chains generate massive amounts of structured and unstructured data, which, when used efficiently, can enable organizations to gain intelligent, actionable insights. Traditional supply chains, that do not make use of data analytics are siloed and slow-moving, with no data being exchanged between processes. This setup calls or Visualization for a host of issues like poor logistics efficiency, limited transparency, high inventory holding costs, poor forecasting leading to stock-outs.

The use of supply chain analytics tools enables organizations to gather, analyze, and act upon the data generated by their supply value chains, and rid themselves of all these issues and create an agile, transparent, robust logistics organization of the future to combat uncertainties.

Book a demo to experience the meaningful insights we derive from data through our analytical tools and platform capabilities. Schedule a demo today!

Request a Free DemoWhat is Supply Chain Data Analytics: Use of Data Analytics to Improve Supply Chain Agility and Responsiveness

Supply chain analytics is the ability to bring data-driven intelligence or Visualization to the end-to-end supply value chain planning, sourcing, manufacturing, delivering by reducing inefficiencies and improving productivity across processes. Data analytics has become a powerful tool for enhancing supply chain efficiency and resilience. By leveraging historical data and identifying trends, organizations can better predict future demand and optimize inventory levels, reducing the risk of stockouts and ensuring smooth operations.

| Key Concept | Explanation |

|---|---|

| Anticipation, Improvisation, and Analytics | – Anticipate potential disruptions and plan contingencies for better response. – Improvisation allows quick adaptation to changes with the help of analytics for decision-making. |

| Enhancing Resilience & Responsiveness | – Combining anticipation, improvisation, and analytics improves supply chain resilience and quick adaptability. |

| Sustainable Supply Chain Management | – Data analytics optimize processes and reduce environmental impact. – Helps identify inefficiencies, optimize logistics, and cut carbon emissions. |

| Data Sharing & Collaboration | – Data sharing among supply chain partners improves efficiency, visibility, and decision-making. – Collaboration through analytics tools enhances the entire network’s performance. |

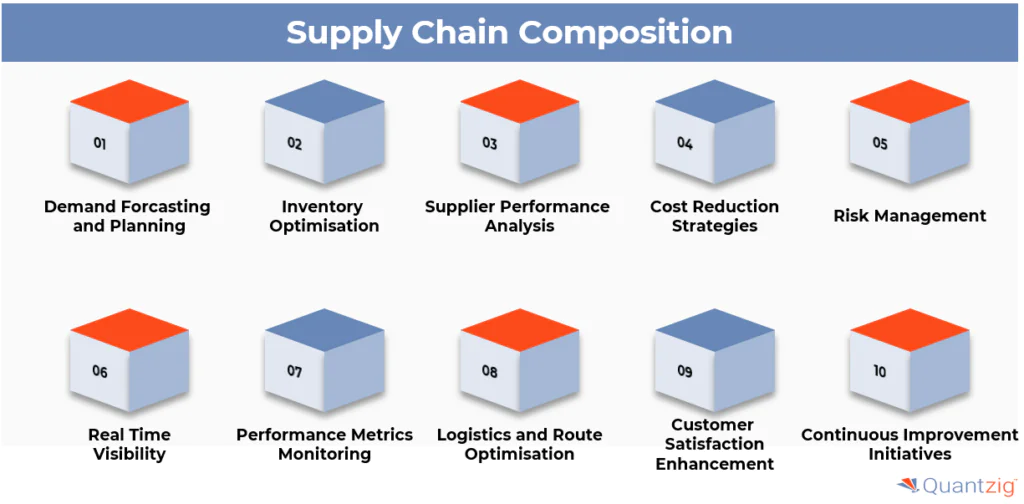

Key aspects of what supply chain data analytics contains:

- Demand Forecasting and Planning: Utilizing historical data and predictive analytics to forecast demand accurately. This aids in planning inventory levels, production schedules, and distribution strategies.

- Inventory Optimization: Analyzing inventory levels, turnover rates, and lead times to optimize stock levels. This minimizes holding costs while ensuring products are readily available to meet demand.

- Supplier Performance Analysis: Assessing the performance of suppliers based on various metrics, such as on-time delivery, quality, and adherence to contractual agreements.

- Cost Reduction Strategies: Identifying areas for cost reduction through data analysis. This may involve analyzing transportation costs, production inefficiencies, and procurement expenses.

- Risk Management: Employing analytics to identify and mitigate potential risks within the supply chain. This risk management includes assessing geopolitical, economic, and operational risks.

- Real-Time Visibility: Implementing analytics tools that provide real-time visibility into the entire supply chain. This enhances responsiveness and allows for proactive decision-making.

- Performance Metrics Monitoring: Establishing key performance indicators (KPIs) and monitoring them regularly to evaluate the overall efficiency and effectiveness of the supply chain.

- Logistics and Route Optimization: Optimizing transportation routes and logistics operations through analytics. This minimizes transit times, reduces fuel costs, and improves overall logistics efficiency.

- Customer Satisfaction Enhancement: Analyzing customer feedback and order fulfillment data to enhance customer satisfaction. This includes improving order accuracy, reducing delivery times, and enhancing overall service quality.

- Continuous Improvement Initiatives: Implementing a data-driven approach for continuous improvement by identifying areas for refinement and innovation within the supply chain.

In essence, evolution of supply chain analytics empowers businesses to navigate the complexities of their supply chains, fostering efficiency, reducing costs, Visualization and ensuring a responsive and adaptive approach to the dynamic landscape of logistics management.

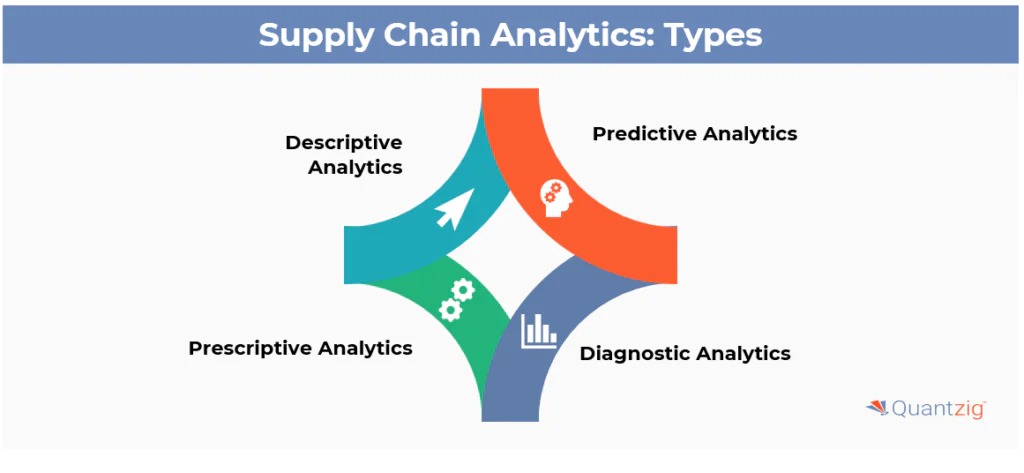

Types of Supply Chain Analytics and How it Works:

Descriptive Analytics:

Descriptive analytics involves examining historical data to understand past performance, Customer experience and identify trends. Businesses use this type of supply chain analytics to gain insights into factors such as inventory levels, demand patterns, and overall operational efficiency. By visualizing and summarizing historical data, businesses can make informed decisions based on a comprehensive understanding of past performance.

Predictive Analytics:

Predictive analytics utilizes statistical algorithms and machine learning to forecast future trends and outcomes for Customer experience. In the context of the supply chain, businesses can predict demand fluctuations, identify potential risks, and optimize inventory levels. By analyzing patterns and correlations in data, organizations can proactively address challenges and capitalize on opportunities.

Prescriptive Analytics:

Prescriptive analytics goes beyond predicting outcomes to provide actionable recommendations. In the supply chain, this involves suggesting optimal courses of action to improve efficiency and address challenges. By leveraging prescriptive analytics, businesses can make data-driven decisions to enhance overall logistics performance.

Diagnostic Analytics:

Diagnostic analytics focuses on understanding the root causes of specific outcomes or issues within the supply chain. By analyzing data to uncover the Data-driven decisions factors contributing to successes or failures, businesses can identify areas for improvement. Diagnostic analytics is crucial for addressing underlying issues and refining processes.

These four types of supply chain analytics collectively empower Sustainable business to extract valuable insights from their data, enabling them to optimize processes, reduce costs, and enhance the overall efficiency of their Sustainable business supply chain. By strategically applying these analytics types, organizations can proactively navigate the complexities of the supply chain, staying agile and responsive to market dynamics.

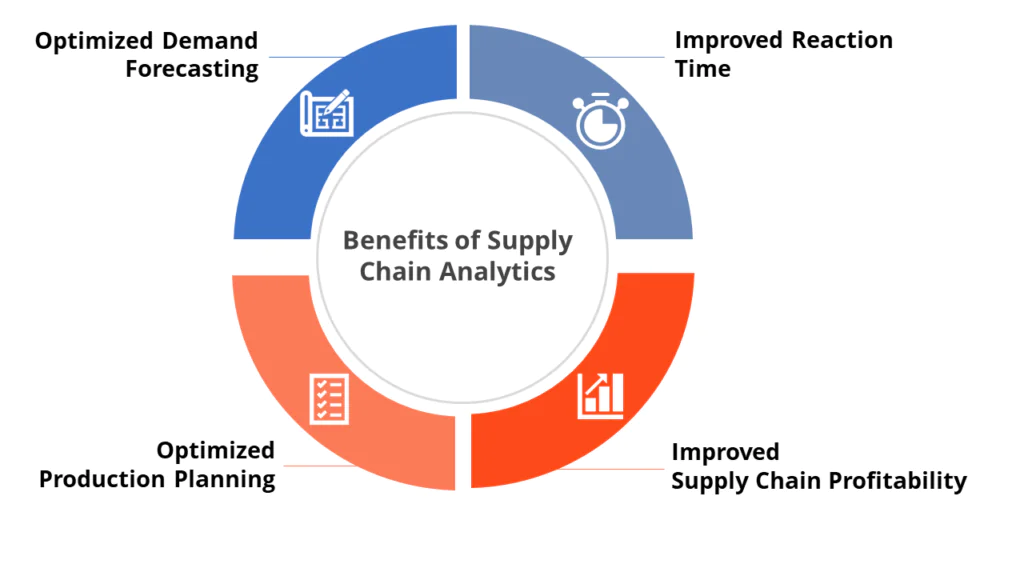

Why is Supply Chain Analytics Important for Business?

Unlike the traditional siloed and slow-moving supply chain, supply chain analytics enables all processes to seamlessly exchange information and create a flexible, optimally integrated network that works in tandem.

- Optimizing Demand Forecasting – By analyzing datasets like POS, order history, competitor strategies, and external impact creators, organizations can improve their demand forecast accuracy. This enables them to optimize inventory levels, reduce lead times, and improve supply chain flexibility.

- Optimizing Production Planning – An agile supply chain makes it easy for the organization to implement changes basis ongoing sales. Bringing about changes in production planning basis latest sales data saves on unnecessary transportation and inventory holding costs and improves overall efficiency.

- Improving Reaction Time – Supply chains are complex, interwoven processes that require time and effort to implement any changes. By creating a flexible supply chain, it becomes easier for organizations to react to bottlenecks and unforeseen issues.

- Reducing Expenses – With optimized sales and operations processes and real-time analysis of the market, supply chain analytics enables organizations to save on unnecessary inventory holding and transportation costs.

All these steps in turn lead to optimization of productivity, budgets, and profitability across the supply value chain.

Speak with Quantzig’s analytics experts to learn how we can help you derive intelligent, actionable insights from complex, unstructured data with minimum effort to drive competitive readiness, market excellence, and success.

Get started with your complimentary trial today and delve into our platform without any obligations. Explore our wide range of customized, consumption-driven analytical solutions services built across the analytical maturity levels.

Start your free trial nowQuantzig – The Solution to all Your Supply Chain Challenges

In a world that is rapidly becoming data-driven, improving supply chain management capabilities has become imperative to companies in order to stay in the competition. Market volatility, dynamic demands, supplier management, and excess spends — all these challenges arise due to lack of robust data-backed supply chain management. Supply chain analytics, therefore, acts as a nexus between industries and the gigantic troves of supply chain information lying at their disposal.

Quantzig’s AI-powered supply chain analytics solutions enable you to gain continuous visibility into all supply chain processes to identify inefficiencies, Cognitive analytics, reduce wastage, spends, and optimize inventory, and make supply chain processes transparent, intelligent, and more data driven. Moreover, importance of data analytics in supply chain are designed to help businesses identify new opportunities within the supply value chain and generate additional returns and maximize revenues.

Continually achieve synchronization and alignment among all supply chain functions and processes, make better-informed decisions, and revolutionize your end-to-end supply chain organization with Quantzig.

Experience the advantages firsthand by testing a customized complimentary pilot designed to address your specific requirements. Pilot studies are non-committal in nature.

Request a free trial nowFuture of Supply Chain Analytics

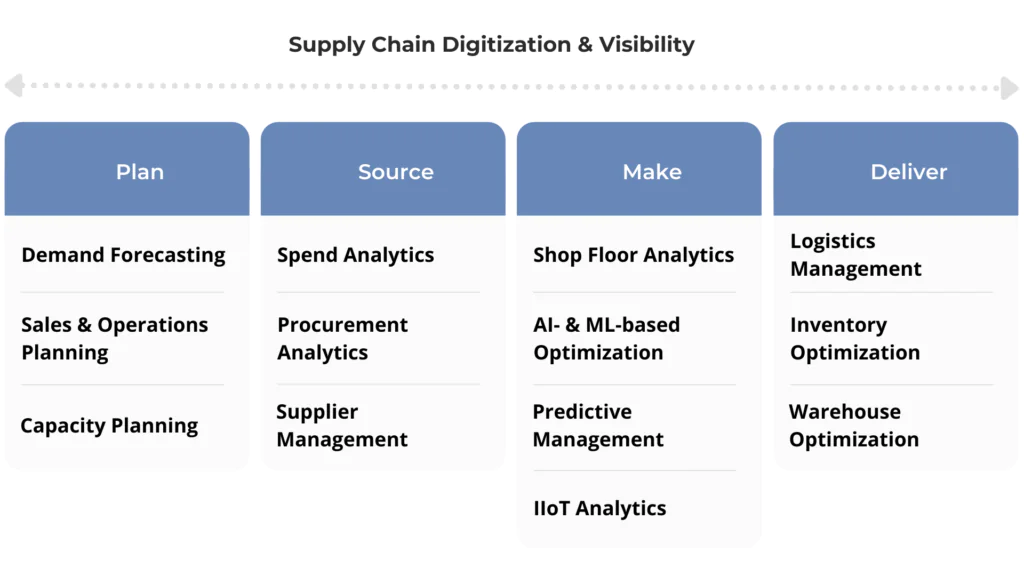

The significance of data analytics in lean supply chain management is underscored by three essential elements: customer-centricity, inter-operability, and agility. With the increasing integration of Artificial Intelligence (AI) and ML, lean supply chains are witnessing a surge in optimization efforts, particularly in demand forecasting, production planning, warehousing, transportation, Cognitive analytics and predictive maintenance. The adoption of IIoT facilitates seamless data exchange among various processes, devices, and systems, enabling real-time monitoring of assets, inventory management, and enhancing overall supply chain performance and visibility. Blockchain technology emerges as a solution to the complexities of global supply chains, Cognitive analytics offering transparency and security by tracking each interaction and transaction. Moreover, the ongoing trend of supply chain digitization revolutionizes manufacturing and delivery processes, enhancing visibility, flexibility, and efficiency across the supply chain network.