Table of Contents

Introduction to Should Cost Analysis Modeling

Businesses tend to gravitate towards value analysis, value engineering, strategic sourcing, and other benchmarking data methods to identify new cost reduction efforts. Given the rapid pace of development across industries, businesses can no longer rely on traditional should cost analysis methodologies but adopt newer should cost modeling software approaches.

Businesses are increasingly turning to should-cost modeling software to optimize costs and improve negotiations. By analyzing cost components of products or services, this AI-powered tool offers a strategic advantage in procurement and supply chain processes. This article explores the challenges and benefits of this game-changing technique and its impact on the negotiation landscape.

Moreover, advanced cost modeling tools enable companies to identify and optimize cost targets. Therefore, this widely accepted approach helps the procurement processes and sourcing teams gain actionable insights that aid price negotiation. It also helps designers and product developers achieve their cost targets by offering detailed cost and pricing insights early, i.e., in the initial product development phase.

What is Should Cost Analysis?

To define the solution in a nutshell, it is an advanced analytics methodology that determines product pricing by evaluating factors like raw material costs, manufacturing overheads, and other related expenses.

Using AI-powered technology, this approach provides a transparent view of true costs through comprehensive should-cost modeling. By analyzing key price drivers, such as market conditions and manufacturing costs, organizations can make informed decisions, identify cost-saving opportunities, and strengthen supplier negotiations. It also promotes cross-functional collaboration among product development, cost engineering, and supply chain teams, enhancing negotiation strategies and fostering long-term supplier relationships.

Book a demo to experience the meaningful insights we derive from data through our analytical tools and platform capabilities.

Request a DemoImportance of Should Cost Model

Often, product designers do not analyze the cost products themselves but instead bank upon sourcing and procurement teams for pricing information. The lack of accurate models leads to sourcing teams negotiating with suppliers with minimal information, resulting in price mismatches and high margins. These models empower businesses to analyze design concepts focusing on the target cost during the development phase, i.e., before the negotiation phase, thereby establishing a practical fail-proof approach to sourcing. Some of the reasons that makes should cost modeling important:

Top 4 Benefits:

Gain a clear understanding of production costs, helping identify cost-saving opportunities and eliminate inefficiencies.

Use accurate cost data to negotiate better pricing and terms with suppliers based on realistic cost benchmarks.

Make informed sourcing and procurement decisions by understanding cost drivers and evaluating alternative materials or processes.

Optimize product design and manufacturing processes to reduce costs, ultimately boosting profitability.

Calculating Should Cost Model Template: A Comprehensive Analysis

This calculation is a meticulous process that plays a pivotal role in procurement and supply chain strategies. It involves leveraging advanced technology, including AI-powered algorithms, to objectively estimate and analyze the various components contributing to the overall cost of a product or service costs.

-

Key Drivers:

Analyzes cost elements like raw materials, labor, logistics, and profit margins to determine factors impacting final product prices.

-

Data Collection:

Combines internal and external data using a top-down approach from ERP systems, invoices, and open sources for accurate cost insights.

-

AI-Powered Technology:

Utilizes AI algorithms to process vast datasets, enhancing accuracy and reducing manual input for efficient calculations.

-

Cleansheet Costing:

Breaks down all production costs for transparency, enabling detailed cost structure analysis and informed negotiations.

-

Cost Projections:

Provides future cost estimates by considering market conditions and raw material price trends, supporting strategic planning.

-

Minimum Manual Input:

Automation minimizes manual work, reducing errors and streamlining processes for procurement efficiency.

-

Supplier Negotiations:

Empowers fact-based supplier negotiations with insights on true costs, fostering improved partnerships and outcomes.

Challenges faced while implementing Should Cost Modeling

Even though the advantages or benefits of the service makes Should Cost an absolute choice with incremental-improvement mindset, it comes with few challenges of its own. Some of them are as mentioned below.

Data Accuracy and Availability:

- Obtaining accurate and comprehensive data for all cost components can be challenging.

- Addressing this challenge involves leveraging advanced data analytics and sourcing strategies.

Dynamic Market Conditions:

- The volatility of market conditions poses a challenge for accurate scenario modeling.

- Overcoming this challenge requires continuous monitoring and agile adaptation to changing market dynamics.

Cross-Functional Collaboration Barriers:

- Ensuring seamless collaboration across diverse business functions can be a hurdle.

- Implementing effective communication channels and fostering a culture of collaboration is essential.

Modeling Complexity:

- These models can become intricate due to the complexity of cost structures.

- Simplifying models without compromising accuracy involves leveraging advanced analytics and modeling tools.

Benefits of incorporating Should Cost Analysis in procurement

Before moving further after going through an understanding of the should cost model meaning, let us also take a quick scan of the benefits that should cost analysis brings to the table for you.

Cost Optimization:

- Should Cost Analysis empowers businesses to identify cost-saving opportunities across the supply chain.

- By optimizing costs, organizations can enhance their profitability and competitiveness.

Negotiation Leverage:

- Armed with comprehensive cost insights, businesses gain a strategic advantage in price negotiations.

- Enables informed and data-driven negotiations, leading to favorable outcomes.

Supplier Relationship Management:

- Building transparent and collaborative relationships with suppliers is facilitated through Should Cost Modeling.

- Organizations can work closely with suppliers to achieve mutual cost efficiencies.

Risk Mitigation:

- Identifying potential risks in the supply chain becomes more effective with Should Cost Analysis.

- Proactive risk mitigation strategies can be implemented to ensure continuity.

Strategic Decision-Making:

- It provides a foundation for strategic decision-making.

- Businesses can align their procurement strategies with overall organizational goals.

Continuous Improvement:

- Regular analysis allows for ongoing refinement of cost models.

- Continuous improvement becomes a key aspect of cost management strategies.

Get started with your complimentary trial today and delve into our platform without any obligations. Explore our wide range of customized, consumption driven analytical solutions services built across the analytical maturity levels.

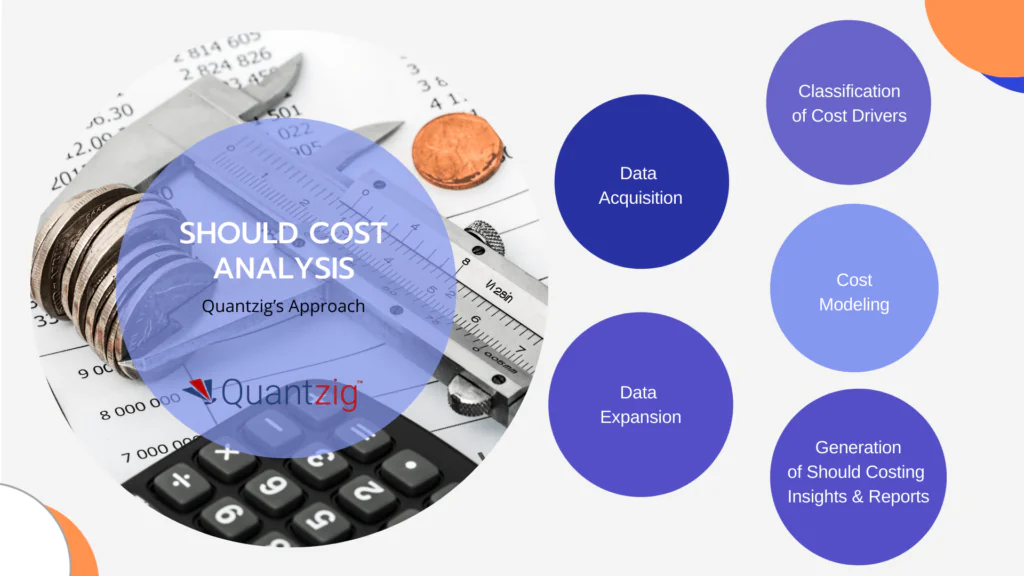

Start your trialShould Cost Analysis Model: Quantzig’s Approach

Since should cost modeling primarily focuses on analyzing the elements that make up the price of a product or service costs, businesses must have a robust analysis model or cost breakdown analysis model to price their products competitively.

To help our clients address this issue, we’ve developed a comprehensive approach to should cost modeling, which involves the following phases –

This methodology involves multiple phases, each contributing to a comprehensive analysis and effective cost management. The following table outlines the key phases involved in the should-cost modeling process:

| Phase | Description |

|---|---|

| Phase 1: Data Acquisition | Gather data from various sources, including ERP platforms, bill of materials, spend data, purchasing invoices, and information on raw materials. |

| Phase 2: Methodical Data Expansion | Analyze collected data sets and cost drivers, such as raw materials, manufacturing overheads, logistics, and labor costs. |

| Phase 3: Classification of Cost Drivers | Classify identified cost drivers into homogeneous groups based on the analysis. |

| Phase 4: Cost Modeling | Outline annual volumes, batch quantities, and units of measure. Define processes and materials with respect to geographical locations. |

| Phase 5: Generation of Should Costing Insights | Develop insights using proprietary cost analysis models, cost breakdown analysis, and price analytics platforms. |

| Phase 6: Reporting | Generate reports with a detailed breakdown of processes, materials, non-recurring engineering (NRE), and authorization costs. |

In summary, the should-cost modeling process involves a detailed examination of data, classification of cost drivers, and the development of strategic insights. This structured approach helps businesses gain a clearer understanding of true costs, ultimately supporting better negotiation outcomes and cost management strategies.

Experience the advantages firsthand by testing a customized complimentary pilot designed to address your specific requirements. Pilot studies are non-committal in nature.

Request a pilotConclusion

Quantzig’s team of 550+ seasoned analytics experts have the expertise and skill it takes to design and build should cost data models tailored to your business’s needs and equip you with data-driven, actionable insights for prudent decision-making. Our approach also helps clients reverse engineer product costs to accurately estimate the price of components. Equipped with detailed pricing insights, businesses will be well-positioned to forge better, more effective contractual agreements and boost overall market competitiveness.