Written By: Associate Vice President, Analytics and Data Strategy, Quantzig

Table of Contents

Introduction to Supplier Performance Management

In the fast-paced modern business world, where supply chains span global markets, the importance of Supplier Performance Management (SPM) has never been more pronounced. In this blog, we delve into the heart of procurement excellence to unravel the top benefits of Supplier Performance Management. From mitigating risks to unlocking operational efficiencies, SPM emerges as a strategic cornerstone for businesses aiming not just to survive but to thrive in an increasingly competitive landscape. Join us as we delve into how cultivating strong partnerships with suppliers can elevate your organization to new heights of success.

Supplier Performance Management (SPM) plays a pivotal role in modern business ecosystems, serving as the essential element that ensures operational efficiency, quality control, and risk mitigation. Delving into the multifaceted advantages of SPM offers a comprehensive view of how organizations can leverage this practice to optimize their supply chain and procurement processes.

Request a demo to experience the meaningful insights we derive from data through our analytical tools and platform capabilities. Schedule a demo today!

Request a Free DemoWhat is Supplier Performance Management?

Supplier performance management is defined as a process that helps businesses analyze, measure, and manage the performance of their suppliers. This enables them to cut costs and drive continuous improvements in their supply chain operations. Supplier performance management involves activities that aim at improving the performance and capability of suppliers. It also ensures that both parties share in the benefits of better quality and performance, shorter cycle times, and lower costs.

By leveraging supplier management solutions, businesses can get Benefits of Supplier Performance Management, identify potential issues and their root causes. Companies mostly rely on timely delivery, price reduction, and service quality offered by their suppliers in order to gain more profit. Therefore, supplier performance management directly impacts the quality of the whole supply chain, making it important to establish an efficient mechanism to ensure the quality of services or products offered. Through supplier performance management, companies can eliminate suppliers who fail to comply with performance requirements. Supplier performance management helps in setting the stage for suppliers to understand the needs and expectations of customers. As a result, a strategic partnership can be built, resulting in an increase in suppliers’ performance and competencies.

Supplier performance metrics bring together the components of risk management, metrics management, supplier segmentation, and consequence management. This combination can help actively manage important supplier relationships in a consistent manner, providing actionable data to facilitate supplier scorecard and supplier selection.

What is the Importance of Supplier Performance Management Process?

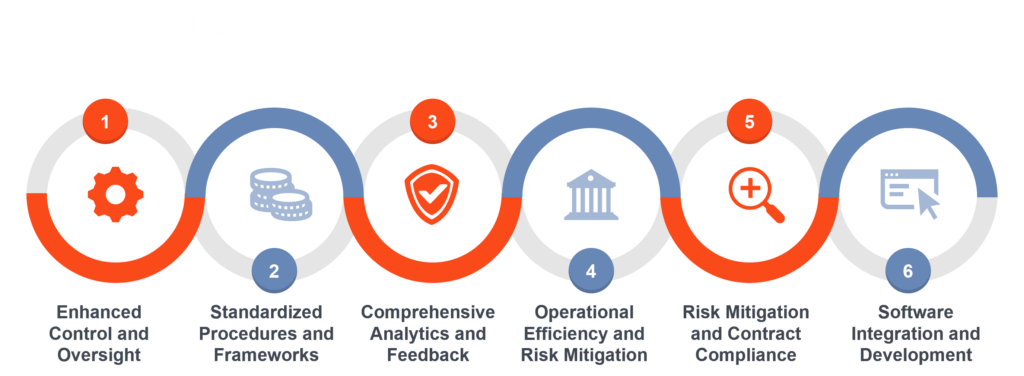

1. Enhanced Control and Oversight

Efficient Procurement Teams and Systems: By implementing SPM, procurement teams can effectively rank vendors based on predefined criteria such as service quality, deliveries, and price points. This structured approach allows for an average rating of vendors, providing insights into their performance. Procurement teams, armed with this data, can then create a list of preferred vendors, ensuring a consistent flow of goods and services that meet organizational needs.

2. Standardized Procedures and Frameworks

One of the primary benefits of SPM is the establishment of standardized procedures and frameworks. These frameworks act as a guiding mechanism for procurement teams, ensuring that all actions align with the organization’s goals and objectives. By adhering to a set framework, companies can maintain a consistent level of service quality across all vendors, reducing the potential for defects or inconsistencies in deliveries.

3. Comprehensive Analytics and Feedback

Utilizing advanced analytics tools, organizations can gather feedback on vendor performance, allowing for data-driven decision-making. These analytics provide insights into areas of improvement, highlighting potential solutions to enhance vendor relationships and overall supply chain efficiency. By collaborating with vendors and conducting demos where necessary, businesses can refine their procurement strategies based on real-time data and feedback.

4. Operational Efficiency and Risk Mitigation

Effective Control Mechanisms: Implementing SPM allows organizations to exert effective control over their supply chains. By setting predefined criteria and standards, companies can evaluate vendors based on their performance against these benchmarks. This proactive approach ensures that vendors meet specific requirements, reducing the risk of market disruptions and supply chain failures.

5. Risk Mitigation and Contract Compliance

SPM enables businesses to identify potential risks associated with vendors, allowing for proactive measures to mitigate these challenges. By establishing robust contracts that outline clear expectations and deliverables, organizations can hold vendors accountable for their performance. This contractual clarity ensures that all parties involved understand their roles, responsibilities, and obligations, fostering trust and transparency in the business relationship.

6. Software Integration and Development

The integration of specialized software solutions facilitates the seamless implementation of SPM practices. These software tools provide organizations with the capabilities to monitor vendor performance, track deliveries, and evaluate service quality effectively. By leveraging software analytics, companies can gain a comprehensive understanding of their market position, enabling them to make informed decisions based on actionable insights.

Experience the advantages firsthand by testing a customized complimentary pilot designed to address your specific requirements. Pilot studies are non-committal in nature.

Request a Free PilotWhat are the Challenges in Supplier Performance Management Process?

Despite its importance, managing supplier performance comes with its set of challenges. One primary challenge is the lack of standardized metrics and measurement systems. Different organizations may prioritize different performance indicators, making it difficult to create a universal benchmark for supplier evaluation.

Another challenge is the dynamic nature of the business environment. Suppliers may face unforeseen issues such as production delays, quality fluctuations, or financial instability. Adapting to these changes and ensuring a consistent level of performance becomes challenging.

Moreover, communication gaps can hinder effective supplier performance management and supplier development. Inconsistent communication between buyers and suppliers may lead to misunderstandings, impacting the overall performance of the supply chain.

Also read: Ensuring Quality Excellence with Supplier Quality Management in CPG: A Low-Code Approach

The Essential Role of Supplier Performance Management in Risk Reduction

Supplier performance management (SPM) plays a crucial role in optimizing supply chain operations, ensuring that businesses maintain a strong relationship with their suppliers while driving continuous improvement. By evaluating key metrics such as delivery timelines, quality, cost-effectiveness, and compliance, SPM helps organizations identify areas of inefficiency and foster collaboration for mutual success.

- Establishing Standards: SPM helps in defining performance standards and expectations, providing a clear framework for suppliers to follow.

- Measurement and Evaluation: It involves the systematic measurement and evaluation of supplier performance against predefined metrics, ensuring transparency and accountability.

- Continuous Improvement: Supplier Performance Management is not a one-time activity; it involves continuous improvement. Feedback and performance data are used to drive ongoing enhancements in supplier performance and supplier collaboration.

- Issue Resolution: When issues arise, SPM provides a structured approach for issue resolution. It allows for timely identification and resolution of problems to prevent long-term disruptions.

How does Supplier Performance Management Process Help Your Business?

- Operational Efficiency: SPM enhances operational efficiency by streamlining processes, reducing delays, and ensuring that suppliers meet delivery timelines and quality standards.

- Competitive Advantage: Effective supplier performance management contributes to a competitive advantage. A reliable and high-performing supply chain is a valuable asset in today’s competitive business landscape.

- Customer Satisfaction: Consistent supplier performance directly impacts the quality of the products or services offered to customers. Meeting or exceeding customer expectations is crucial for long-term success.

- Adaptability to Changes: In a dynamic business environment, SPM helps businesses adapt to changes in the market, technology, or regulatory requirements by ensuring that suppliers can adjust accordingly.

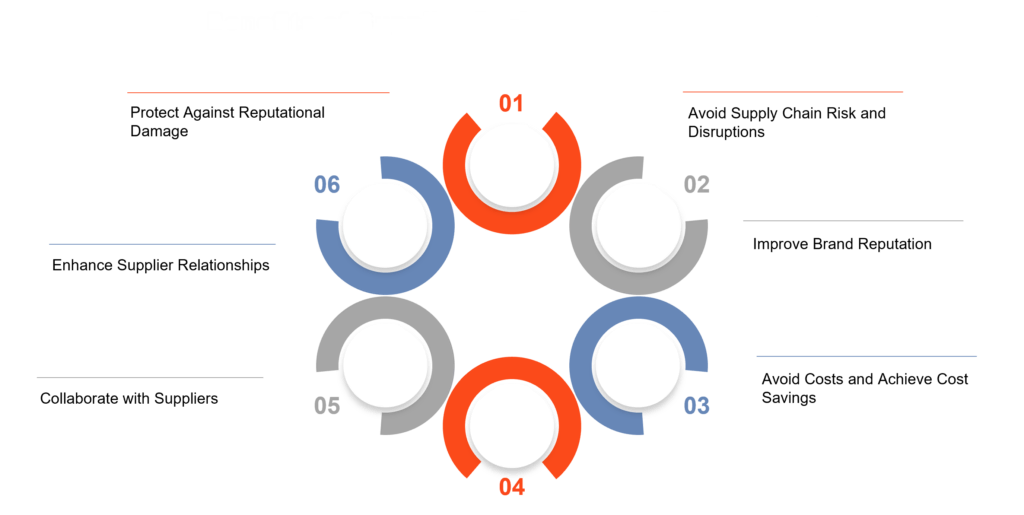

Supplier Performance Management: Key Advantages for Your Supply Chain

Effective Supplier Performance Management (SPM) has become a critical strategy for organizations seeking to optimize their supply chains, mitigate risks, and drive continuous improvement. By closely monitoring and managing the performance of their suppliers, companies can unlock a range of benefits that positively impact their overall business operations and competitiveness.

| Key Benefit | Description |

|---|---|

| Avoid Supply Chain Risk and Disruptions | Familiarity with third-party vendors helps prevent interruptions and reduce risk exposure. Supplier performance management (SPM) provides visibility into risks, allowing businesses to take preventive measures to ensure smooth supply chain operations. |

| Improve Brand Reputation | SPM tracks supplier performance against KPIs, enabling businesses to take early corrective actions, which improves brand reputation by maintaining quality and reliability in the eyes of customers. |

| Avoid Costs and Achieve Savings | SPM helps track cost factors and centralizes supplier data, leading to better cost management and increased savings by improving decision-making and resource allocation. |

| Collaborate with Suppliers | SPM facilitates the collection of supplier data, fostering collaboration, setting common goals, and establishing trust. This leads to better contract management, strategic sourcing, and stronger supplier relationships. |

| Enhance Supplier Relationships | Regular performance reviews and open communication improve supplier relationships, aligning expectations and creating shared goals, ultimately enhancing supply chain performance and mutual benefits. |

| Protect Against Reputational Damage | SPM helps vet new suppliers and continuously monitor their performance, ensuring adherence to quality, reliability, and ethical standards, safeguarding the company’s reputation. |

This table summarizes the key benefits of Supplier Performance Management (SPM) for businesses, helping them enhance supply chain efficiency, reduce risks, and build stronger supplier relationships.

How to Assess Supplier Performance?

By leveraging advanced Supplier Performance Management tools, including SPM software and supplier scorecard solutions, organizations can monitor key metrics, address supplier quality problems, and foster continuous improvement. This structured approach not only mitigates supplier risk factors but also optimizes the supplier’s performance, ultimately driving better business outcomes.

| Action | Description |

|---|---|

| Implement an SPM Program | Establish a comprehensive Supplier Performance Management (SPM) program to track and evaluate supplier performance. |

| Use SPM Software | Integrate SPM software for systematic data tracking and performance management. |

| Leverage an SPM System | Utilize an integrated SPM system to track key metrics and address supplier risks. |

| Define KPIs | Set clear key performance indicators (KPIs) aligned with business objectives to assess supplier performance. |

| Use Supplier Scorecards | Implement scorecards to visualize and track supplier performance against KPIs. |

| Support Continuous Improvement | Regularly review performance data to drive continuous supplier quality improvements. |

| Integrate Supplier Lifecycle Management | Manage the entire supplier relationship with a supplier lifecycle management solution. |

| Address Supplier Risk Factors | Conduct regular assessments to mitigate financial, regulatory, and other supplier risks. |

| Utilize Advanced SPM Tools | Leverage advanced tools for strategic decision-making and enhanced supplier performance management. |

In summary, assessing supplier’s performance effectively requires a comprehensive approach that integrates a robust Supplier Performance Management, SPM program with the right software, tools, and solutions. This approach ensures thorough monitoring, fosters continuous improvement, and effectively manages the supplier lifecycle.

Experience the advantages firsthand by testing a customized complimentary pilot designed to address your specific data statistics requirements. Pilot studies are non-committal in nature.

Request a Free PilotConclusion

In conclusion, Supplier Performance Management offers a plethora of benefits that transcend traditional procurement practices. By focusing on areas such as efficient control mechanisms, risk mitigation, and operational efficiency, organizations can cultivate strong vendor relationships, supplier monitoring, optimize their supply chains, and drive sustainable growth. Embracing the principles of SPM empowers businesses to navigate the complexities of modern markets with confidence, ensuring that they remain competitive, resilient, and poised for success.