Analytics in the chemical industry has become a transformative force, driving efficiency, innovation, and strategic decision-making across this vital sector. As a cornerstone of modern manufacturing, the chemical industry plays a critical role in converting petroleum and natural gas into intermediate materials that are essential to countless everyday products. With over 30 years of advancements in manufacturing software, analytics in the chemical industry has enabled organizations to optimize operations, enhance supply chain management, and improve sustainability efforts.

According to Quantzig experts, the industry boasts a global workforce of nearly 20 million people and generates annual sales of approximately US$5 trillion. Leveraging analytics in the chemical industry, companies can harness data-driven insights to refine production processes, boost profitability, and remain competitive in an evolving market landscape.

Analyzing data sets to glean knowledge and insights that can inform better decisions is known as data analytics. Data analytics is being quickly adopted by the manufacturing sector, and the chemical manufacturing sector is no different. Analytics in the chemical industry plays a huge role in the manufacturing of chemicals, helping to improve production processes, lower costs, optimize supply chains, and improve safety. The importance of data analytics in chemical manufacturing and how it is changing the sector will be discussed in this article.

Request a demo to experience the meaningful insights we derive from data through our analytical tools and platform capabilities. Schedule a demo today!

Request a Free DemoTable of Contents

What is the Importance of Data Analytics in the Chemical Industry?

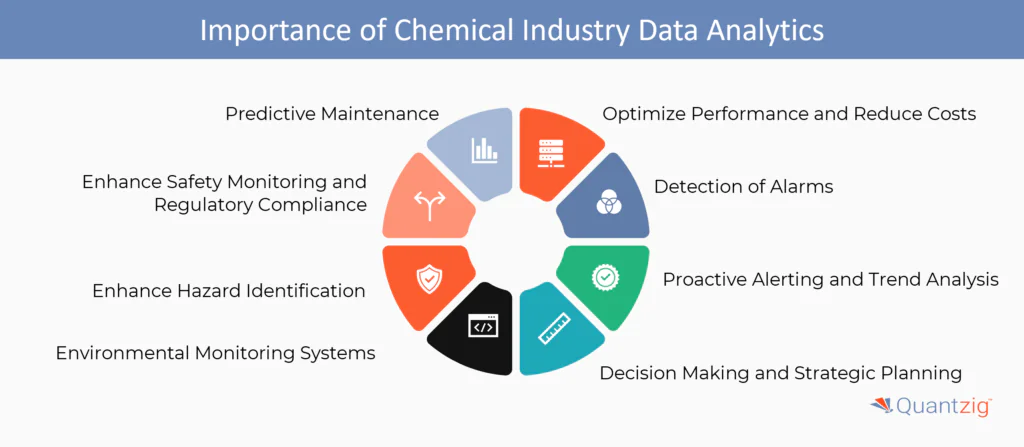

Analytics in the chemical industry plays a pivotal role in enhancing predictive maintenance and asset management. This sector, characterized by complex chemical manufacturing processes and heavy regulation, relies heavily on the efficient functioning of equipment such as turbines and compressors. Here’s how analytics plays a crucial role:

1. Predictive Maintenance with Chemical Industry Data Analytics:

Sensors attached to chemical industry equipment generate a continuous stream of data. Analytics harnesses this data to perform early identification of equipment issues and implement preventive maintenance. This analysis of sensor and control system data helps predict potential breakdowns, preventing machinery failures and reducing downtime. The outcome is increased equipment reliability and a significant impact on production schedules and profitability.

2. Optimizing Performance and Reducing Costs:

By comparing data from similar equipment across the industry, chemical companies can optimize the performance of their machinery. This process not only enhances productivity but also plays a critical role in cost reduction. Predictive maintenance with chemical industry data analytics leads to a more efficient use of resources, minimizing waste generation and cutting costs in areas like raw materials, labor, and equipment.

3. Enhancing Safety Monitoring and Regulatory Compliance:

In a sector where safety is a priority, real-time monitoring of safety parameters through analytics is vital. Identifying and mitigating safety risks through advanced analytics enhances the overall safety in manufacturing. Furthermore, ensuring compliance with industry regulations becomes more manageable with analytics, as monitoring and reporting necessary data become more efficient and accurate.

Analytics in the chemical industry, specifically in the context of preventive maintenance and asset management, contributes significantly to optimizing production processes, energy efficiency, and safety monitoring. It’s an approach that not only addresses the challenges of the chemical manufacturing process but also contributes to the sustainable and competitive future of the industry.

4. Detection of Alarms Through Advanced Analytics in the Chemical Industry

The chemical industry, dealing with substances that are often hazardous, necessitates stringent safety measures. The detection of alarms through analytics is a crucial aspect of managing the risks associated with the production, storage, and transportation of chemicals. Here’s how analytics is transforming this critical area:

5. Enhancing Hazard Identification and Safety Monitoring:

Analytics plays a pivotal role in continuously monitoring the levels of explosive gases such as hydrogen, oxygen, sulfide, nitrogen dioxide, sulfur dioxide, and carbon monoxide. By efficiently monitoring and lowering these levels, analytics helps prevent potential mishaps or explosions that could cause significant damage to life and property. The real-time monitoring of safety systems and hazard identification is essential in enhancing overall safety in manufacturing.

6. Proactive Alerting and Trend Analysis:

Advanced analytics enables chemical companies to proactively identify safety risks and alert operators, thus preventing dangerous situations. By analyzing trends and patterns in safety-related data, analytics offers predictive insights, allowing for timely corrective actions and trend analysis.

7. Regulatory Compliance and Environmental Monitoring Systems:

In an industry heavily regulated to ensure environmental sustainability, analytics aids in compliance monitoring. Environmental monitoring systems powered by analytics help manage waste and reduce environmental impact, ensuring the industry’s operations align with public pressure for more environmentally friendly products and practices.

8. Decision Making and Strategic Planning:

The insights provided by analytics in the detection of alarms are not just for immediate safety management. They also inform strategic decisions and planning, allowing chemical companies to anticipate and prepare for potential safety challenges. This foresight is crucial in maintaining a reputation for safety and reliability in a highly competitive industry.

Get started with your complimentary trial today and delve into our platform without any obligations. Explore our wide range of customized, consumption driven analytical solutions services built across the analytical maturity levels.

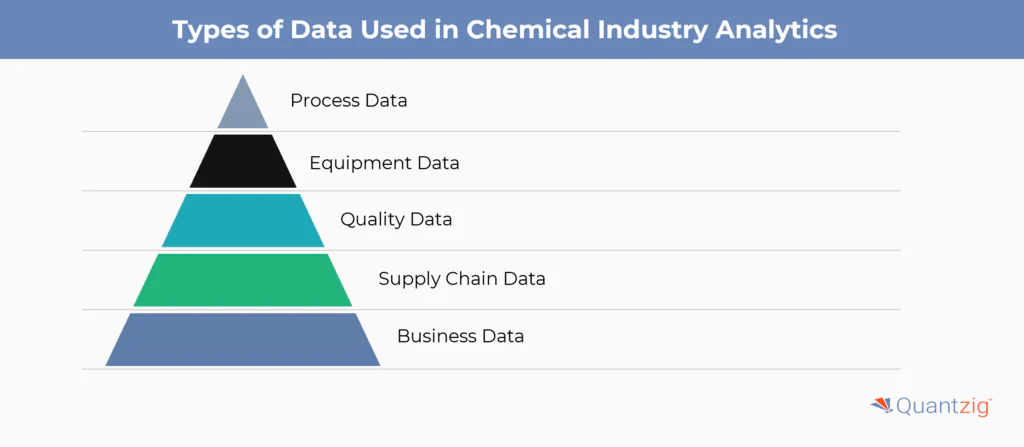

Start your Trial nowTypes of Data Used in Chemical Industry Analytics

The chemical industry generates vast amounts of data from various sources that can be leveraged for analytics to optimize processes, improve product quality, and enhance safety. The main types of data used in chemical industry analytics include:

1. Process Data

This includes data from sensors, control systems, and laboratory analysis that capture the parameters of chemical processes, such as temperature, pressure, flow rates, and chemical compositions. Process data is critical for monitoring process performance, detecting anomalies, and optimizing process conditions.

2. Equipment Data

Data from production equipment, such as pumps, valves, and reactors, provides insights into the condition and performance of assets. This includes data on equipment vibration, temperature, and operating hours, which can be used for predictive maintenance to prevent unplanned downtime.

3. Quality Data

Data on product quality, such as purity, yield, and specifications, is essential for ensuring consistent product quality and meeting customer requirements. Quality data can be used to identify the root causes of quality issues and optimize process parameters to improve quality.

4. Supply Chain Data

Data on raw material inventory, supplier performance, and logistics can help optimize supply chain operations and reduce costs. This data can be integrated with process and quality data to provide a holistic view of the manufacturing process.

5. Business Data

Financial data, sales data, and market data can be combined with manufacturing data to optimize business decisions, such as pricing, product mix, and capacity planning.

Integrating these diverse data sources into a unified analytics platform is crucial for deriving meaningful insights and driving continuous improvement in chemical manufacturing. However, this integration can be challenging due to the complexity of chemical processes and the need for specialized expertise in data management and analytics.

How Can Analytics in the Chemical Industry Help in Cost Reduction?

Energy management is a critical aspect of the chemical industry, where operations are dynamic and complex. The use of advanced analytics and smart manufacturing techniques is revolutionizing this domain:

1. Optimizing Energy Consumption:

Advanced analytics, through the use of soft sensors and other smart manufacturing technologies, enables the processing of numerous data points to select optimal operating conditions. This process significantly enhances energy efficiency in chemical manufacturing. By monitoring and managing energy consumption and identifying opportunities for efficiency improvement, companies can substantially reduce energy-related costs.

2. Improving Operational Efficiency and Sustainability:

The integration of analytics into energy management contributes not only to cost reduction but also to environmental sustainability. By reducing energy consumption and minimizing environmental impact, chemical companies address climate change concerns while optimizing their operations. This commitment to sustainable products and environmentally friendly practices is increasingly vital in the face of rising public pressure for environmental responsibility.

3. Supply Chain Optimization and Waste Reduction:

Energy efficiency also ties into broader aspects of the chemical industry, such as supply chain optimization and waste reduction. Analytics helps in analyzing and optimizing supply chain processes, improving efficiency, and cost-effectiveness, while simultaneously reducing waste generation. This holistic approach is key to creating a sustainable future for the chemical industry.

4. Strategic Decision-Making for Industry Growth:

The role of analytics in energy management extends beyond operational improvements. It informs strategic decision-making, enabling companies to navigate challenges such as rising costs and increased competition. By making informed decisions based on data insights, chemical companies can increase their competitiveness and contribute to innovation and growth in the industry.

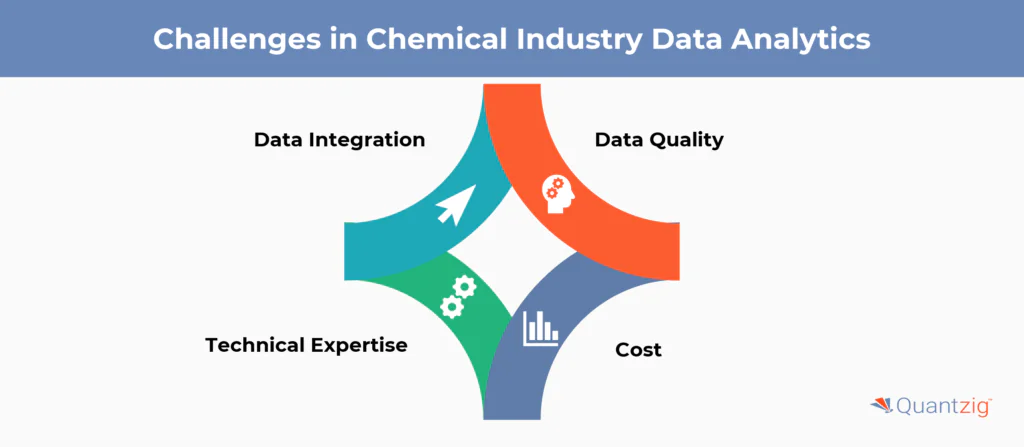

Challenges in Implementing Data Analytics in Chemical Manufacturing

The chemical manufacturing industry is undergoing a significant transformation driven by the concepts of Industry 4.0, which emphasize state-of-the-art automation and seamless data exchange for faster and better-informed decision-making. Data analytics is an essential component of this revolution, as it enables deriving contextualized insights from various disparate data sources to unlock value and optimize production processes.

While the potential benefits of data analytics in chemical manufacturing are substantial, there are several challenges that organizations must overcome to implement it effectively. These challenges include:

1. Data Integration

Chemical manufacturing generates vast amounts of data from numerous sources, such as sensors, control systems, and laboratory analysis. Integrating this data into a unified system for analysis can be a complex and resource-intensive process, requiring significant technical expertise to aggregate data from different types of sensors, store the information in various platforms, and ensure seamless integration.

2. Data Quality

Ensuring data quality is critical for effective data analytics. Incomplete, inaccurate, or inconsistent data can lead to incorrect conclusions and poor decision-making. Maintaining data quality necessitates robust data collection and validation processes, as well as ongoing monitoring and maintenance.

3. Technical Expertise

Effective data analytics requires specialized skills in data management, statistical analysis, and machine learning. Finding professionals with the necessary expertise to manage and analyze data effectively can be a challenge for many organizations. Chemical companies need to invest in building these capabilities in-house to ensure that data experts understand the intricacies of chemical processes.

4. Cost

Implementing data analytics in chemical manufacturing can be costly, requiring significant investments in hardware, software, and personnel. Organizations must carefully weigh the potential benefits against the costs of implementing data analytics solutions.

To overcome these challenges and unlock the full potential of data analytics in chemical manufacturing, organizations should prioritize high-value use cases, invest in upskilling current employees, embrace the convergence of Information Technology (IT) and Operational Technology (OT), and adopt technology at a pace that works for the organization.

Real-time Analytics Applications in Chemical Processes

Real-time analytics is transforming chemical manufacturing by enabling continuous monitoring, optimization, and control of processes. Key applications include:

- Process Monitoring: Real-time data from sensors is analyzed to track key performance indicators, detect anomalies, and identify opportunities for improvement.

- Predictive Maintenance: Analytics models predict equipment failures before they occur, allowing for proactive maintenance and reduced downtime.

- Quality Control: Real-time monitoring of product quality parameters ensures consistent product specifications and reduces off-spec production.

- Yield Optimization: Analytics models optimize process parameters to maximize yield and selectivity, while minimizing waste and energy consumption.

- Environmental Monitoring: Real-time tracking of emissions and effluents enables compliance with environmental regulations and early detection of issues.

By harnessing the power of real-time analytics, chemical manufacturers can improve operational efficiency, product quality, safety, and sustainability. However, successful implementation requires overcoming challenges in data integration, quality, and analytics expertise.

How Can Quantzig Help You with Chemical Industry Analytics?

Quantzig, a leading advanced analytics service provider, offers comprehensive solutions to help chemical manufacturers harness the power of data analytics. Their expertise spans across the chemical value chain, enabling clients to optimize processes, enhance product quality, and drive operational efficiency.

Quantzig’s solutions leverage cutting-edge technologies like machine learning, artificial intelligence, and predictive analytics to deliver actionable insights. Their team of domain experts works closely with clients to identify high-impact use cases, develop customized analytics models, and implement scalable solutions that drive measurable business outcomes.

By partnering with Quantzig, chemical companies can unlock the full potential of their data, make informed decisions, and stay ahead of the curve in a rapidly evolving industry landscape. Our end-to-end analytics services, from data integration to advanced analytics and visualization, empower clients to transform data into a strategic asset and achieve sustainable growth.

Experience the advantages firsthand by testing a customized complimentary pilot designed to address your specific requirements. Pilot studies are non-committal in nature.

Request a Free TrialConclusion

In summary, the application of analytics in the chemical industry marks a significant shift towards more efficient, sustainable, and competitive operations. From enhancing predictive maintenance and asset management to optimizing energy management, analytics empowers the industry to address its core challenges. These include managing rising costs, navigating increased competition, and achieving environmental sustainability.

The insights gained from data analysis applications, such as customer feedback analysis and market trends analysis, are instrumental in driving product innovation, optimizing production processes, and ensuring regulatory compliance. As the chemical industry continues to evolve, the integration of analytics will remain pivotal in transforming manufacturing processes, optimizing supply chains, and enhancing safety measures. By embracing data and analytics, the chemical industry is well-positioned to overcome industry challenges and create a brighter, more sustainable future.