Written By: Sudeshna Ghosh

Table of Contents

Introduction to Smart Factory Trends

Over the past few years, the manufacturing industry has undergone a major digital transformation with relentless technological advancements evolving the COVID-19 pandemic, and consumer demands serving as catalysts for rapid changes. This article delves into the dynamic realm of modern manufacturing, unraveling the intricate tapestry of innovations that redefine industry norms. From integrating cutting-edge technologies like the Internet of Things (IoT) and Artificial Intelligence (AI) to optimizing processes through data-driven analytics, the evolution of smart factories heralds a new era of efficiency, sustainability, and unparalleled productivity. As industries worldwide embark on the transformative journey towards smart manufacturing, this exploration navigates the key trends shaping this evolution, offering insights into the symbiotic relationship between technology and manufacturing prowess.

Request a demo to experience the meaningful insights we derive from data through our analytical tools and platform capabilities. Schedule a demo today!

Request a Free Demo

Revolutionizing Manufacturing Efficiency: A Smart Factory Transformation with Quantzig

Client details:

A leading manufacturing company located in Europe.

Challenges Faced by the Client:

- The client grappled with formidable challenges centered around the enhancement of decision-making and planning processes within their smart factories. A pressing concern was the need to bolster productivity in response to the ever-shifting landscape of dynamic manufacturing schedules.

- Critical processes such as demand smoothening, manufacturing scheduling, material planning, maintenance planning, and quality control proved to be excessively labor-intensive, leading to operational inefficiencies. The manual nature of these processes rendered them susceptible to errors, undermining the precision required for optimal production.

- Recognizing the urgency to align with contemporary industry standards, the client sought solutions to streamline these labor-intensive processes, harnessing the power of advanced technologies to enhance accuracy, efficiency, and overall productivity within their smart factory ecosystem.

Solutions Offered by Quantzig:

- QZ delivered a comprehensive solution to address the client’s challenges by seamlessly integrating a plug-in into their existing ERP systems. This innovative plug-in seamlessly aggregated data from the ERP platform, sensors, and connected devices, consolidating it into an efficient data architecture within the Microsoft Azure system.

- The transformative integration of automated solutions ensued, encompassing demand management, manufacturing scheduling, and production management. Leveraging predictive maintenance and automated quality control solutions, driven by cutting-edge computer vision technology, further elevated operational efficiency.

- By automating these crucial processes, the client experienced a substantial reduction in labor requirements within the production workflow. This not only optimized resource allocation but also significantly accelerated the decision-making process.

- The holistic implementation of these solutions not only addressed the client’s immediate challenges but positioned their smart factories for sustained growth, aligning seamlessly with the demands of dynamic manufacturing schedules while enhancing overall productivity and operational resilience.

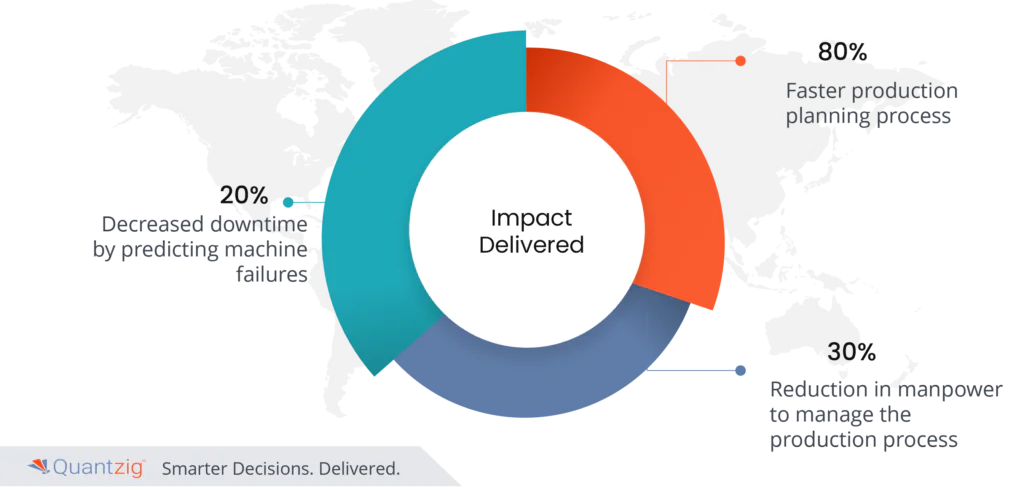

Impact Delivered:

- Decrease downtime by 20% by predicting machine failures.

- 80% faster production planning process.

- 30% reduction in manpower to manage the production process

Technologies implemented:

Azure, Power platforms, Azure AI

Experience the advantages firsthand by testing a customized complimentary pilot designed to address your specific requirements. Pilot studies are non-committal in nature.

Request a Free PilotImportance of Smart Factory Trends for Manufacturing Industries:

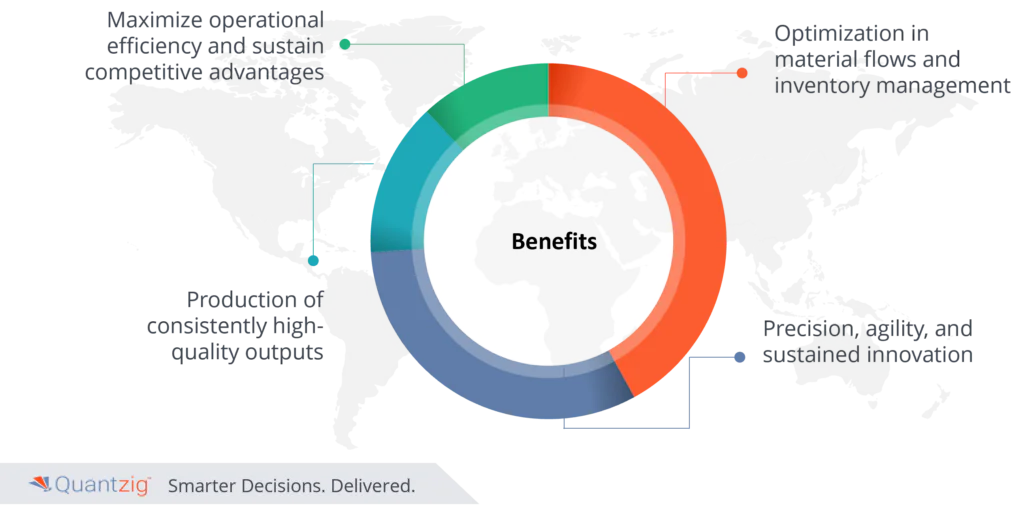

- In the contemporary landscape of manufacturing, the adoption of smart factory trends stands as a strategic imperative for industries seeking to maximize operational efficiency and sustain competitive advantages. The crux lies in harnessing the wealth of data generated by sensors, machines, and interconnected devices. Through the application of advanced analytics and Artificial Intelligence (AI), this data becomes a transformative toolkit, empowering teams to elevate efficiency, streamline processes, and make data-driven decisions that resonate with profound business value.

- Smart factories leverage this data-driven intelligence across multifaceted domains. Process optimization becomes a nuanced exercise, with insights garnered from analytics enabling fine-tuning and augmentation of production processes. Supply chains benefit from enhanced visibility and adaptability, ensuring optimization in material flows and inventory management. Predictive maintenance, another critical facet, becomes proactive and cost-effective, reducing downtime and extending the lifespan of equipment.

- Quality control, underpinned by advanced analytics, transcends traditional boundaries. It evolves into a dynamic process, capable of real-time monitoring and adaptive adjustments, ensuring the production of consistently high-quality outputs. In essence, the comprehensive integration of advanced analytics and AI across the spectrum of smart factories represents a paradigm shift, steering manufacturing industries toward a future characterized by precision, agility, and sustained innovation. Embracing these trends isn’t merely an option; it is a strategic imperative to thrive in an era where data is the cornerstone of operational excellence.

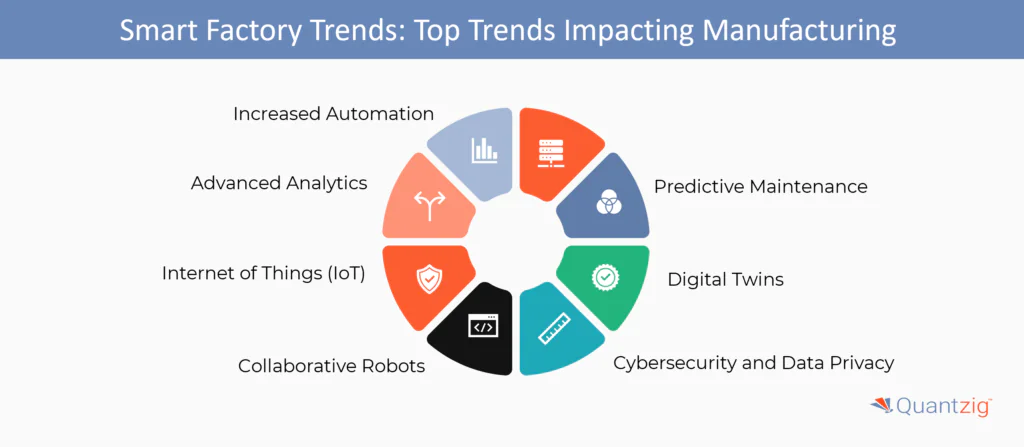

Smart Factory Trends: Top Trends Impacting Manufacturing

Trend 1: Increased Automation

Automation is becoming increasingly prevalent in smart factories, with the integration of advanced technologies like robotics and artificial intelligence. This trend enhances efficiency, reduces labor costs, and improves product quality. Automation also enables the handling of complex tasks, freeing human workers to focus on higher-value tasks.

Trend 2: Advanced Analytics

Smart factories rely heavily on advanced analytics to optimize production and reduce waste. This includes the use of machine learning algorithms to analyze large data sets and predict maintenance needs. Advanced analytics also enables real-time monitoring and adjustments to production processes, ensuring optimal efficiency.

Trend 3: Internet of Things (IoT)

The IoT plays a crucial role in smart factories by connecting devices and machines, enabling data exchange and automation. This trend enhances real-time monitoring, predictive maintenance, and streamlined workflows, leading to improved efficiency and reduced downtime.

Trend 4: Collaborative Robots (Cobots)

Cobots are gaining popularity in smart factories due to their ability to work alongside human workers. These versatile automation machines take on repetitive, hazardous, and less desirable tasks, freeing employees to focus on higher-value functions.

Trend 5: Artificial Intelligence (AI) and Machine Learning

AI and machine learning are transforming smart factories by enabling advanced predictive maintenance, quality control, and supply chain optimization. These technologies also help in demand forecasting and product customization, leading to improved customer satisfaction.

Trend 6: Predictive Maintenance

Predictive maintenance is a key component of smart factories, enabling the identification of potential equipment failures before they occur. This trend reduces downtime, improves efficiency, and extends the lifespan of equipment.

Trend 7: Digital Twins

Digital twins are virtual replicas of machines or systems, enabling innovation and creativity with minimal risk. This trend allows for real-time monitoring and simulation, enhancing awareness of factory status and optimizing production processes.

Trend 8: Cybersecurity and Data Privacy

Cybersecurity and data privacy are critical concerns in smart factories, as they rely heavily on connectivity and data exchange. This trend involves implementing robust safeguards to protect intellectual property, sensitive data, and manufacturing systems from unauthorized access.

Smart factory trends are transforming the manufacturing landscape, enabling increased efficiency, reduced costs, and improved product quality. By embracing these trends, manufacturers can stay competitive and resilient in a rapidly changing market.

Get started with your complimentary trial today and delve into our platform without any obligations. Explore our wide range of customized, consumption driven analytical solutions services built across the analytical maturity levels.

Start your Free Trial TodayConclusion

In conclusion, manufacturers who invest in cutting-edge technologies and embrace smart factory trends will be well-positioned in this globally competitive marketplace in the upcoming years. By adopting advanced capabilities and features and more sustainable practices, manufacturing companies can create a more sustainable future for their businesses, the planet, and the industry. As we navigate the transformative landscape of advanced analytics, AI, and interconnected systems, it becomes evident that embracing these smart factory trends isn’t just an evolution; it’s an imperative for survival and prosperity. The symbiotic relationship between innovation and efficiency is not only reshaping production methodologies but also propelling industries into an era of unparalleled productivity and sustainable growth.