In the dynamic landscape of supply chain management, the ability to forecast demand accurately is paramount for success. This article delves into the crucial realm of demand forecasting, unraveling its significance and the pivotal role it plays in effective supply chain management. Explore the strategic methodologies, tools, and best practices that empower businesses to anticipate market trends, optimize inventory, and make informed decisions. Discover how demand forecasting transforms challenges into opportunities, enhancing resilience, reducing costs, and ultimately ensuring customer satisfaction. Join us on a journey to master the art of demand forecasting for a resilient and efficient supply chain.

Table of Contents

Role of Demand Forecasting:

The supply chain management world is set to take a new direction as various industries move forward in technological progress. This article will focus on how demand forecasting impacts the entire management of the supply chain in the diverse and complex market of the European Union. Instead of relying solely on older methods, new techniques like big data, analytics, and machine learning are used to give us a deeper understanding of what the market needs are. In the European Union, demand forecasting has become a great advantage due to the precise monetary, cultural, and regulatory variations it presents. Proper forecasting is necessary to optimize all aspects of the supply chain such as manufacturing, warehousing, and distribution. Disrupted forecasts can cause a ripple effect known as the ‘bullwhip effect’ which can lead to unfavorable impacts across the entire chain of logis6cs. This can cause unsa6sfied customer needs, lower service level agreements (SLAs), increased pressure on manufacturing, added constraints on logis6cs, and profit margin cuts. Exploring modern demand forecasting techniques plays a critical role in ensuring that the supply chain operates efficiently. Enhancing the supply chain’s capability to quickly and efficiently respond to changes and streamlining processes all hinge on the accuracy of the forecast.

Challenges Faced:

Supply chain management is a detailed tapestry that many businesses have to deal with and in particular demand forecasting. There are various challenges that businesses face in demand forecasting, especially in the supply chain management context. Tremendous fluctuations characterize the market characterized by quick changes that nobody saw coming. In addition, customer preferences are influenced by various factors as the market today has become consumer driven leading to increasing volatility. Such behavior of consumers contributes to a more complex prediction of demand which can be quite confusing. Similarly, seasonality adds another dimension to the difficulty given its cyclical effect on consumer behaviors and market trends. This brings about additional uncertainties as new products are introduced into the market. sometimes, we don’t know how the market will react to these new entrants hence complicating the process of forecasting. It takes not only an insight into future trends and customers’ reactions but also a good understanding of present prevailing market dynamics for one to predict how product changes or launches will impact on them. Moreover, modern supply chains are often structured on multi-level bases making forecasting difficult. The presence of multiple tiers of suppliers, manufacturers and distributors make these networks complex systems where there is no easy way of making accurate predictions.

Top Benefits of Demand Forecasting for Enterprises:

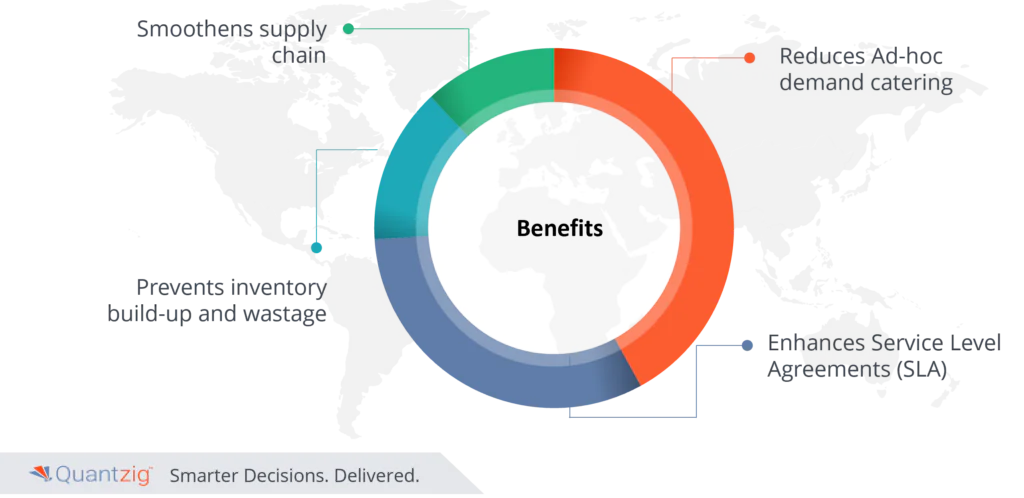

Demand forecasting plays a crucial role, in smoothening the supply chain through better planning. It reduces the need for ad-hoc demand catering by predicting future demands , leading to a more streamlined process. Additionally it enhances the service level agreements (SLA) between companies making it an essential aspect of coordination and planning to optimize operations. The achievement of excellence, customer satisfaction and cost efficiency in supply chain management heavily relies on demand forecasting. This valuable tool helps optimize resource utilization by aligning supply with expected demand thereby preventing inventory build-up and wastage.

How Quantzig can help you?

Quantzig specializes in enhancing demand forecasting processes by identifying and fixing existing gaps in predictive modelling. The method involves assessing the customer’s current forecasting methodology to find areas for improvement. Quantzig develops robust forecast models that can make highly accurate predictions using advanced techniques. These models are refined through iterative loops so that they align closely with real market trends. A key aspect of Quantzig’s offerings is the focus on exhaustive feature engineering. By carefully choosing and optimizing inputs of the forecast model improves forecast output accuracy greatly. That manner, the models grow to be both powerful and customized to a particular client’s market dynamics. Quantzig’s main goal is to offer businesses with precise and reliable demand forecasting for better planning and decision making. With experts in senior analytical jobs as well as machine learning experts makes Quantzig a valuable partner to organizations that wish to optimize their supply chains and respond flexibly to changes in demand patterns. With Quantzig’s help, businesses should experience a significant improvement in their forecasting capabilities, leading to enhanced operational efficiency and competitive advantage.

Success Story:

Revolutionizing Supply Chain Management for a CPG Giant

Client details:

A leading Consumer Packaged Goods (CPG) company located in the European

Union.

Challenges Faced by the Client:

The client encountered many complications with its supply chain due to constant demand changes. This negatively impacted their supply chain efficiency and made customers dissatisfied and affected the overall service level agreement (SLA). Moreover, these supply chain expenses increased due to many ad-hoc adjustments. The key issue behind those supply chain difficulties was that the forecasting process used by this company did not adequately capture variations in market and customer demands. In response, the client needed to enhance accuracy in their current forecasting process at a very short notice.

Solutions Offered by Quantzig:

1. In response to these challenges, Quantzig came up with a strategic approach. The first thing the team at Quantzig did was to try and identify possible gaps in the current forecasting process of the client, especially in feature building.

2. Embracing the advanced k-fold validation framework, a robust forecasting model was developed, one that can mimic the actual market conditions as closely as possible. This took place through numerous iterative loops that fine-tuned the model for maximum accuracy.

3. In order to minimize errors in this forecast, an exhaustive feature engineering was done by Quantzig. The choice and refinement of inputs to the forecasting model also made the solution more powerful but also tailor-made to suit particular market dynamics of its client.

Impact Delivered:

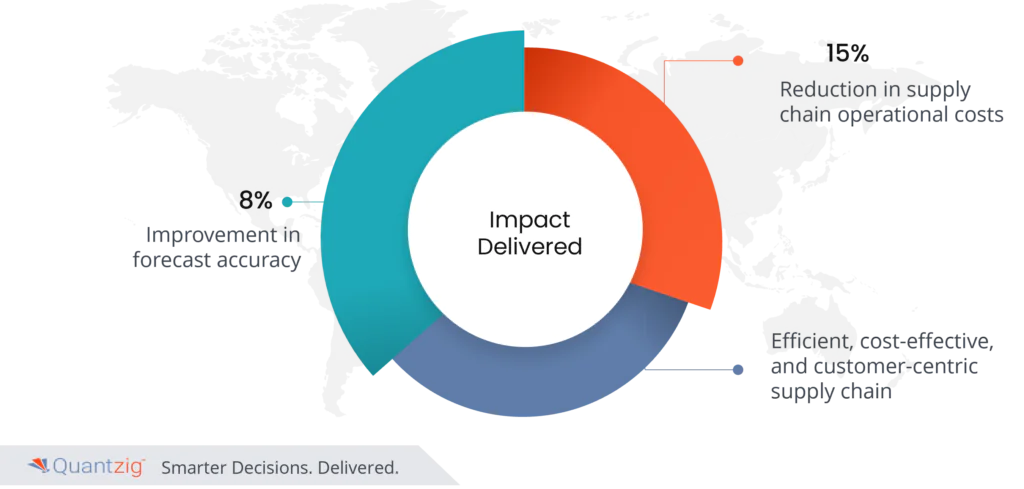

Remarkable improvements were realized through the applica6on of Quantzig’s solution. The forecast accuracy increased by 8% which played a significant role in enhancing the planning of supply chain operations. Improved forecas6ng precision led to smoother operations hence, reduced supply chain operation costs by 15%. Therefore, the client could quickly adapt to the market changes thus aligning their supply chain processes with the market and customer needs.

This consumer-packaged goods (CPG) behemoth’s success is a testament to how effective demand forecasting can be. The client was able to overcome its hurdles with help from Quantzig and this has paved the way for a more efficient, cost-effective, and customer-centric supply chain.

Related Articles

- 3 Amazing Retail Analytics Trends You May Not Have Known

- 3 Best Practices Businesses for Managing a Successful Retail Analytics Campaign

- 3 Ways to Improve Retail Price Optimization Strategy

- 30% Reduction in Employee Turnover Rates Achieved by Retail Chain Through the Implementation of Turnover Prediction Models