Written by: Sudeshna Ghosh

Table of Contents

Introduction to AI Inventory Management

In the intricate world of supply chain business, the seamless flow of goods from raw materials to the end customers represents a complex network of strategic planning, procurement, logistics, production, and distribution. Each step is orchestrated to optimize efficiency, minimize cost, and ensure superior customer satisfaction through automation. The advent of AI inventory management has introduced a transformative approach, integrating the prowess of artificial intelligence (AI) and data analytics to revolutionize inventory handling with the help of automation.

At the core of AI inventory management lies the power to optimize every step of this complex journey. By implementing AI and machine learning, businesses can accurately forecasts demand, manage inventory levels at warehouse, and streamline operations, leading to significant improvements in efficiency, warehouse management, and customer service.

As we dive deeper into the world of AI inventory systems management, we will explore its transformative impact on supply chain businesses, addressing common challenges, stock replenishment, and unveiling the advantages it brings to the table.

Connect with us for tailor-made solutions.

The Challenges in Supply Chain Business Without AI

The supply chain business, without the integration of AI and automation, faces numerous challenges that can hinder operational efficiency and growth. Let’s delve into these significant hurdles:

1. Manual Demand Forecasting: Traditional methods of demand forecasting, which often rely on manual processes and human intervention, are prone to errors and inaccuracies. This can lead to critical issues like stockouts or surplus inventory, adversely affecting operational efficiency and customer satisfaction.

2. Lack of Real-Time Insights: Operating without the advantage of real-time insights can leave businesses way in the dark, hindering information based decision-making. This lack of timely data analytics prevents companies from staying ahead of the curve, for example: capitalizing on opportunities and maintaining a competitive edge.

3. Inefficient Inventory Management: Inventory management Methods without AI often resorts to guesswork, manual warehouse management, and manual tracking, leading to low stock replenishment, increased carrying costs, and unhappy customers. These inefficiencies can have a ripple effect throughout the entire supply chain.

4. Supply Chain Disruptions: In today’s interconnected global market, supply chain disruptions are a common challenge. Without AI’s predictive analytics, businesses struggle to proactively identify and mitigate potential disruptions, leading to increased costs, warehouse automation, automated inventory, automated warehouse operations, and customer dissatisfaction.

5. Ineffective Supplier Management: Managing suppliers without the support of AI can be challenging. Manual processes often result in poor communication, suboptimal supplier selection, and inconsistent delivery timelines and quality of the products.

6. Limited Optimization Opportunities: Managing complex optimization tasks like inventory allocation, capacity utilization, and route planning is challenging without AI. Manual processes often lack the precision and efficiency that AI-driven insights and algorithms can provide.

These challenges highlight the necessity for AI integration in modern supply chain operations. The next section will explore the transformative advantages of AI inventory management.

Advantages of Supply Chain Business with AI Inventory Management:

In the dynamic landscape of supply chain management, integrating Artificial Intelligence (AI) unfolds a realm of possibilities. Let’s explore the transformative impact of AI on various facets of supply chain operations:

Integrating Artificial Intelligence (AI) in inventory control management brings a multitude of transformative benefits to the supply chain business:

1. Accurate Demand Forecasting: AI elevates demand forecasting to new levels of precision. By meticulously analyzing extensive datasets, AI algorithms enable businesses to anticipate market trends, make smart inventory, and reduce the stockouts of the Companies, reshaping strategic planning for future demands.

2. Real-Time Insights: AI offers real-time visibility across the supply chain, providing up-to-the-minute data on supplier performance, warehousing automation, computer vision, customer demand, and inventory levels. This capability ensures agile, informed decision-making, allowing businesses to swiftly respond to market dynamics.

3. Enhanced Inventory Optimization: AI serves as a powerful tool for inventory management, working continuously to minimize excess stock and streamline inventory levels, thereby optimizing operational workflows and enhancing efficiency.

4. Proactive Supply Chain Management: AI’s predictive analytics and machine learning capabilities enable early detection of potential risks and disruptions, allowing warehouse managers to maintain uninterrupted operations and implement preventive strategies.

5. Streamlined Supplier Collaboration: AI facilitates improved collaboration with suppliers through automated order processing and reporting, inventory control, and real-time tracking. This enhanced interaction ensures timely deliveries, improved supplier relationships, and consistent product quality.

6. Optimization of Logistics and Route Planning: AI revolutionizes logistics by crafting efficient routes and optimizing transportation processes. This leads to improved delivery times, reporting, streamlined transportation, and heightened customer satisfaction.

In essence, AI emerges as a pivotal force in reshaping supply chain dynamics, positioning businesses for a future marked by efficiency and resilience.

Also read: Ensuring Quality Excellence with Supplier Quality Management in CPG: A Low-Code Approach

Conclusion: Embracing the Future with AI Inventory Management

AI inventory management is not just a technological upgrade; it’s a strategic revolution in supply chain operations. By embracing AI, warehouse managers are poised to achieve unprecedented levels of efficiency, cost savings, increase Orders, and customer satisfaction. This technology stands as a testament to the immense potential of AI management software in transforming supply chains, propelling businesses into a future where success is defined by intelligent decision-making and operational excellence.

Success Story:

Quantzig’s AI Inventory Management Revolution for a US-based Retailer

Quantzig recently collaborated with a leading US-based retailer to overhaul their AI inventory management. Faced with challenges like demand uncertainty and inefficient inventory management, the retailer sought Quantzig’s expertise in AI-driven solutions.

Challenges:

The client grappled with several critical challenges that hindered their supply chain efficiency:

- Inaccurate manual demand forecasting leading to stockouts of Items and missed sales data opportunities.

- Struggles in optimizing inventory levels, causing increased carrying costs.

- Lack of real-time insights, resulting in reactive market responses.

Connect with us for tailor-made solutions.

Solutions:

We collaborated closely with the client, delivering innovative ai inventory management solutions to address their unique challenges:

- AI-Driven Demand Forecasting: Quantzig implemented advanced AI algorithms for accurate demand forecasting, optimizing inventory allocation.

- Optimized Inventory Management: AI management software was used to dynamically adjust stock levels based on real-time demand, improving fulfillment rates.

- Real-time Analytics Dashboard: Provided actionable insights into market trends and demand patterns for proactive decision-making.

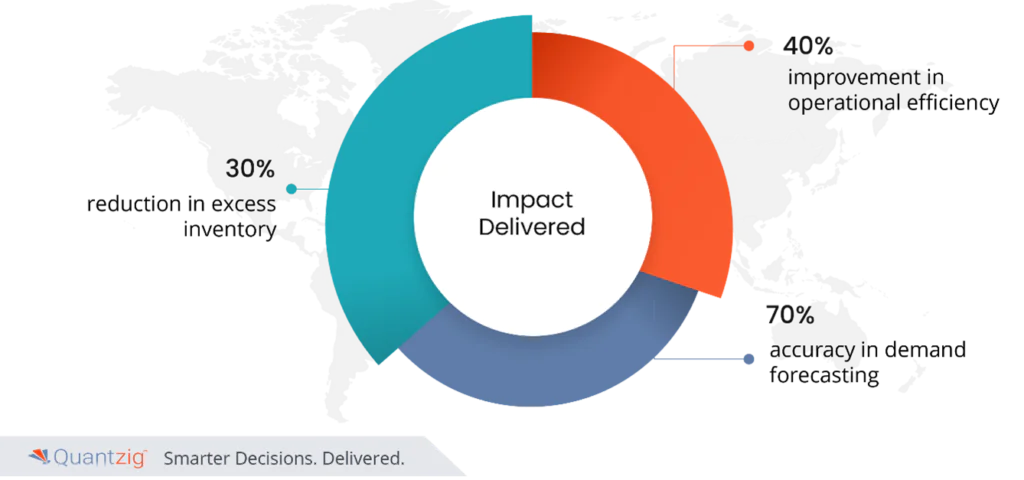

Impact Delivered:

- 30% reduction in excess inventory

- 40% improvement in operational efficiency

- 70% accuracy in demand forecasting

This success story highlights Quantzig’s capability in transforming supply chain operations through AI, setting the stage for businesses to excel in today’s competitive market.

FAQs on AI Inventory Management

- How can AI improve inventory management? AI enhances inventory management system by providing accurate demand forecasting, real-time insights, and optimized stock levels, leading to reduced stockouts and improved efficiency.

- What are the benefits of using AI in inventory management? Benefits include improved forecasting accuracy, enhanced inventory optimization, proactive supply chain management, and streamlined supplier collaboration.

- How does AI optimize inventory levels? AI Technology uses algorithms to analyze data trends and adjust inventory levels dynamically, ensuring optimal stock Quantities and reducing excess inventory.

- What industries can benefit from AI inventory management? Industries like retail, manufacturing, e-commerce, and logistics can significantly benefit from AI inventory management.

- What are some popular AI inventory management tools? Popular tools include AI-powered ERP system, predictive analytics software, and AI-integrated inventory management platforms.