Author: Associate Vice President, Analytics and Data Strategy, Quantzig.

Table of Contents

Key Takeaways:

- The landscape of the innovative inventory management solutions is expanding while also becoming increasingly interconnected.

- Artificial intelligence, data analytics, and cloud-based software have emerged as indispensable tools in contemporary of these innovations.

- Current trends indicate a shift towards faster, more cost-effective, and more dependable supply chains and distribution networks.

Introduction to Inventory Management Innovation

Striving to be better with smart inventory management in today’s ecosystem, possessing a comprehensive understanding of managing your space is essential for smooth business operations and is a key factor in achieving success. This is where inventory management innovations come into play, serving a critical role in optimizing stock levels, reducing expenses, and enhancing the bottom line through enhanced visibility, streamlined stock management, improved operational efficiency, and cost savings.

Book a demo to experience the meaningful insights we derive from data through our analytical tools and platform capabilities. Schedule a demo today!

Request a Free DemoWhat is Inventory Management?

Inventory management is the process of overseeing and controlling a company’s inventory, including the acquisition, storage, and sale of goods. It ensures that the right quantity of items is available at the right time, minimizing costs and preventing overstock or stockouts. Effective inventory management is crucial for optimizing operations, improving cash flow, and maintaining customer satisfaction.

Benefits of Using Quantzig’s Inventory Management Innovation services for your Business

Our supply chain and inventory management solutions are instrumental in uncovering opportunities by meticulously assessing the cost and time allocated at each juncture within the supply chain, spanning from production to delivery. With our inventory risk analysis and warehouse monitoring tool, your team can swiftly pinpoint materials susceptible to wastage, swiftly identify underlying causes, and proactively address risks with tailored recommendations from the tool. This empowers you to address a multitude of the warehouse management queries, ranging from strategic to tactical considerations:

- Identify warehouses exhibiting higher levels of inventory risk (%) and those experiencing shifts in demand variability within inventory optimization technology.

- Assess specific materials within warehouses, quantifying the extent and nature of inventory risk (e.g., expiry wastage, understock), and categorizing them into ABC/XYZ classification buckets.

- Analyse customer order patterns contributing to heightened inventory risk and identify clients requiring assistance in forecasting, order variance management, or lead time optimization to mitigate risk.

- Receive prompt decision support through recommendations for adjustments in material forecasting, alterations to routing plans, and revisions to lead times.

Concisely, Quantzig’ s comprehensive suite of supply chain and inventory management solutions offer unparalleled insights and actionable intelligence to optimize your operations. By leveraging advanced analytics and monitoring tools, we enable you to proactively address the challenges, minimize risks, and enhance overall efficiency. With our expertise, your organization can confidently navigate the complexities of modern supply chains, driving sustainable growth and maximizing profitability. Experience the transformative power of data-driven decision-making with our innovative solutions tailored to meet your evolving needs.

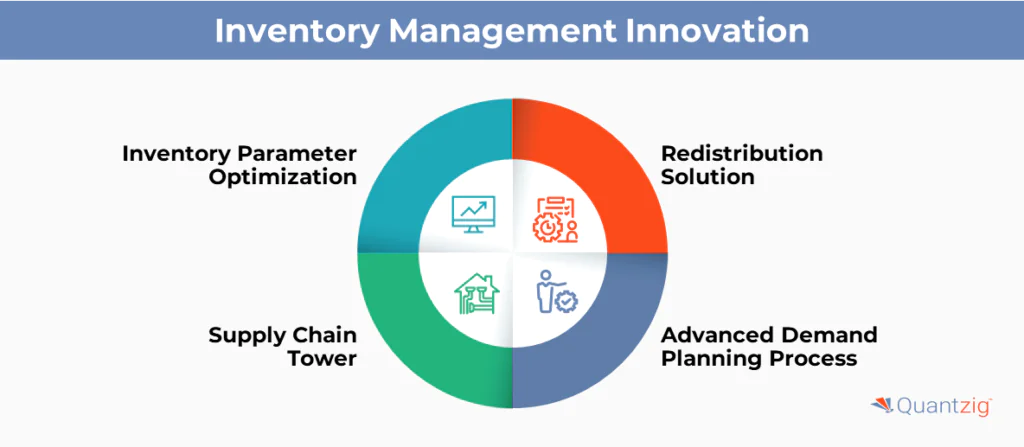

Quantzig’ s Inventory Management Innovation Services

At Quantzig, we specialize in revolutionizing your inventory and warehouse planning with our integrated inventory management solution. At Quantzig, we recognize the critical factors influencing your inventory levels, including customer demand, forecasting accuracy, and supply chain constraints. With our comprehensive suite of services, we empower you to not only pinpoint the root causes of inventory mismanagement but also implement practical solutions that optimize your inventory and drive sustainable growth.

- Redistribution Solution: Experience our innovative approach to addressing excess or deficit inventory in your warehouses. Our redistribution plans are meticulously crafted based on multi-echelon product availability, ensuring optimal stock levels across your entire network.

- Advanced Demand Planning Process: Harness the power of innovative algorithms to uncover hidden trends within your data. Our advanced demand planning process delivers actionable forecasts tailored to your unique needs, utilizing custom algorithms to adapt to changes in material demand seamlessly.

- Supply Chain Tower Solutions: Gain invaluable insights into your supply chain with our comprehensive tower solutions. Enjoy a bird’s eye view of your operations, supported by automated alert systems that enable proactive management by exception.

- Inventory Parameter Optimization: Stay ahead of the curve with our dynamic inventory parameter optimization solution. As customer demand evolves, so do the parameters, and our solution simplifies this complex process by dynamically reconfiguring parameters based on stock on hand, days of supply, expiry wastage, and distribution costs.

In a rapidly evolving business landscape, the ability to effectively manage inventory is paramount to success. With Quantzig, you are not just getting a solution – you are gaining a trusted partner committed to helping you navigate the complexities of inventory management with confidence. Unlock the full potential of your inventory and warehouse operations today with our transformative solutions tailored to meet your specific needs.

Experience the advantages firsthand by testing a customized complimentary pilot designed to address your specific requirements. Pilot studies are non-committal in nature.

Request a free pilotA glance at Quantzig’ s innovation Management Solution Success Story

| Client Location | Unites States |

| Client Problem | Recently, we partnered with a prominent food and beverage manufacturer grappling with rising inventory expirations due to ineffective inventory management practices. This manufacturer boasts over 50 manufacturing sites and serves a clientele exceeding 200. Operating across various Southeast Asian nations, most of their demand originates from North America and Western Europe, contributing to elevated levels of expired stock. |

| Quantzig’ s Solution | Owing to globally dispersed manufacturing operations, maintaining minimal levels of stock became imperative, resulting in losses stemming from product obsolescence. Moreover, the seasonal fluctuations in demand across North America, coupled with supply disruptions in Southeast Asia, posed significant challenges in achieving supply chain agility and formulating an effective inventory management strategy. Understanding these complexities, Quantzig developed a solution to precisely determine the optimal inventory levels required at each warehouse for every SKU. For SKUs already present in warehouses, Quantzig implemented workflows to flag items based on shelf availability. Furthermore, we enhanced the capability to identify inventory unsuitable for sale at a particular warehouse and devised a cost-effective method to transfer them to alternate locations. |

| Impact Created | Enhanced visibility into inventory in near real-time. Achieved a remarkable 17% decrease in losses attributed to obsolescence. Realized a significant 25% reduction in instances of stockouts. |

Get started with your complimentary trial today and delve into our platform without any obligations. Explore our wide range of customized, consumption driven analytical solutions services built across the analytical maturity levels.

Start your free trialWhat is Inventory Management System?

It is at model that guides businesses in optimizing their production processes, from managing raw materials to fulfilling customer orders efficiently. Factors like industry specifics and production lifecycle considerations dictate the selection of the most suitable model to maximize investments in goods and materials.

Understanding inventory models is crucial for resource optimization, cost control, and timely delivery of quality goods. Techniques such as just-in-time (JIT) and materials requirement planning (MRP) help balance inventory for complex manufacturing and supply chain operations. Additionally, models like economic order quantity (EOQ) and days sales of inventory (DSI) offer valuable insights.

While smaller businesses may rely on manual tracking, larger corporations’ benefit from specialized software solutions for inventory management. Once a model is chosen, the focus shifts to leveraging technology and processes to gain a competitive edge.

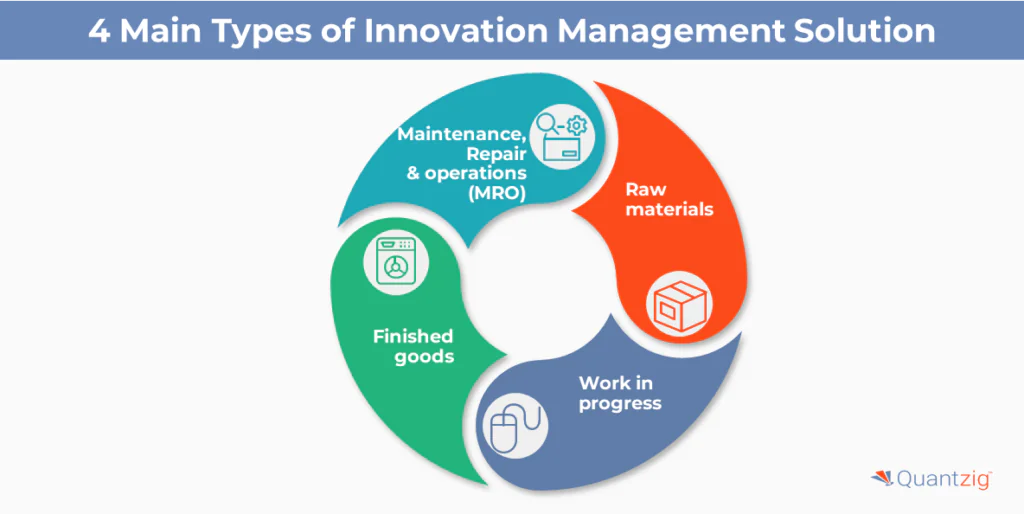

4 Main Types of Inventory Tracking System:

In the intricate world of inventory management solutions, understanding the various categories of goods is fundamental. From raw materials to finished products, each stage of the production process requires careful consideration and management. Let us delve into the essential categories of inventory to gain a deeper understanding of their significance in the supply chain.

- Raw materials: This category encompasses both nonperishable materials, such as sand, wood, or wool, and perishable items like fruits, vegetables, grains, or meats used in the production of processed foods.

- Work in progress: WIP denotes items undergoing production but not yet finished for sale, like glass panels, window frames, textiles, or raw flour.

- Finished goods: Finished goods are products ready for sale, including items like windows, suit coats, or loaves of bread. These goods may serve as intermediate products for further manufacturing processes, such as fabric for clothing production or bread for use in sandwiches, or as final consumer products destined for retail or direct-to-consumer sales.

- Maintenance, repair, and operations (MRO): MRO items are essential for sustaining production operations, encompassing tools, spare parts, and consumables like paint or packaging necessary to maintain equipment or facilitate product distribution.

Importance of Best Inventory Management Solutions:

Inventory models represent the frameworks utilized by businesses to establish and optimize the most efficient methods for maintaining essential inventory levels. While various methods exist for inventory management, no single approach suits every circumstance.

These models aid in determining the most suitable method among the array of options available and subsequently maximizing its efficiency. Some of the diverse inventory models employed by businesses include:

- Just in Time (JIT): Valuable for minimizing storage and inventory overheads, yet vulnerable to supply chain disruptions and price fluctuations.

- Days Sales of Inventory (DSI): Effective for managing perishable goods and optimizing space in smaller retail outlets.

- Materials Requirement Planning (MRP): Essential for ensuring a reliable supply of manufacturing materials across complex supply chain processes.

- Centralized Inventory Model (CIM): Beneficial for controlling inventory levels and tracking goods movement to minimize shrinkage.

- Economic Order Quantity (EOQ): Optimal for minimizing overall inventory costs, encompassing order, shortage, and holding costs.

Additionally, businesses employ various other inventory models in specific contexts, while technological advancements increasingly pave the way for hybrid and combined models that harness the strengths of multiple approaches.

Top 7 Trends in Best Inventory Management Systems

Automation, AI, ML, and cloud-based tools are transforming warehouse operations, enhancing productivity, supply chain inventory management, and reducing expenses. Below is a breakdown of key strategies that highlight these advancements.

| Strategy | Details |

|---|---|

| Warehouse Automation | Automating processes with AI, ML, and robotics helps reduce labor costs. Automation options are expanding as technology costs decrease and wage rates increase. |

| Multi-Warehousing | Distributed inventory management using multiple sites improves supply chain efficiency and speeds up delivery. Cloud-based inventory management makes multi-warehousing more viable. |

| Intelligent Inventory Forecasting | AI-driven forecasting enables businesses to make informed purchasing decisions by predicting inventory needs based on data trends. |

| Customization & Personalization | Tailored inventory recommendations based on customer behavior improve anticipation of future purchases, optimizing stock levels. |

| Predictive Picking | Data analytics and IoT help optimize product placement in warehouses, reducing travel time and improving picking efficiency. |

| AI & ML for Inventory Enhancement | AI/ML systems analyze inventory movement, reducing costs by identifying weaknesses, such as packaging inefficiencies. Integration with IoT strengthens these insights. |

| Cloud Technology for Hybrid Work | Cloud-based inventory management allows seamless data synchronization across locations and supports remote/hybrid work setups, improving overall efficiency. |

These strategies are reshaping warehouse management, making operations more flexible, scalable, and cost-efficient. By adopting these technologies, businesses can stay ahead of the competition and meet growing consumer demands with greater precision and speed.

Conclusion:

Leveraging real-time inventory tracking and AI in inventory management, businesses can now optimize operations like never before. By implementing cloud-based inventory solutions alongside inventory management software, companies can automate and streamline processes, ensuring efficient inventory processes across all locations. Adopting inventory management best practices, such as automated inventory control and demand forecasting in inventory, helps minimize stock shortages and overstock issues. Furthermore, warehouse inventory innovation through AI-driven insights and automation is transforming supply chains, enabling businesses to respond quickly to fluctuating demands and market conditions.

With the help of advanced analytics and innovative solutions like those offered by Quantzig, organizations can navigate the complexities of these with confidence, unlocking new opportunities for growth and success.